Air-conditioned and dustproof control cabinet for CNC machining center

Air-conditioned and dustproof control cabinet for cnc machine contains all the elements and electrical and electronic components needed to control the machining on a CNC machining center. It is properly sealed and cooled by heat exchangers so that dust does not penetrate inside. An air conditioner was used to ensure optimal working conditions for electronic CNC control systems in extremely unfavorable external conditions. On the front wall of the cabinet there is a control panel with all the elements needed to operate the CNC. In addition, test treatment is carried out using a portable handheld remote with a speed governor, function selection buttons and an emergency stop. In the control cabinet there is also a PC computer used to store ready-made machining programs and to communicate the operator with the CNC machine.

Electric control cabinet components:

- main electric switch placed on the cabinet doors;

- operator’s control panel;

- remote control panel;

- PC computer for operator-machine communication (CPU, keyboard, mouse, LCD screen, Ethernet card, 5-ports switch);

- OSAI OPENkey CNC controller (full digital);

- YASKAWA servo-drives;

- air conditioner and heat exchanging system;

- full dust-proof system.

The cabinet is executed with conformity to the IP54 standard.

█ IMPORTANT

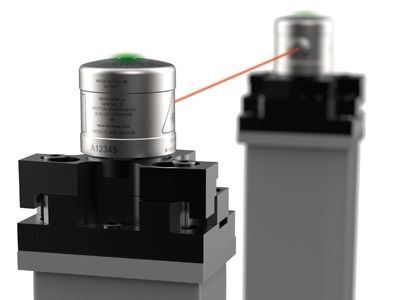

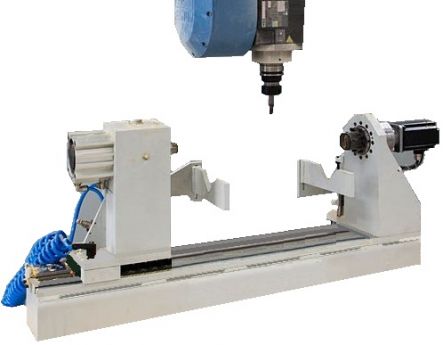

All of the Fanum machining centers are equipped with servo drives and absolute-type encoders. These encoders provides advantage: there is no necessary to execute of the “homing” operation, what is normally executed after every of electric power turn-on, in example after power fading or normal switch-on of the machine at the begining of working day.

█ ELECTRIC ENERGY SAVING SYSTEM

The machine is equipped with a special, electronic controlled system for electric power consumption reduction. That system switch off machine electrical systems being out of using to the stand-by mode. Function of the system is activated by adjustable timer after the machine complete of the working cycle and there is no operator action.

Thanks to the above mentioned system, it is possible to save of electric power, what is normally lose during normal working time interruptions.