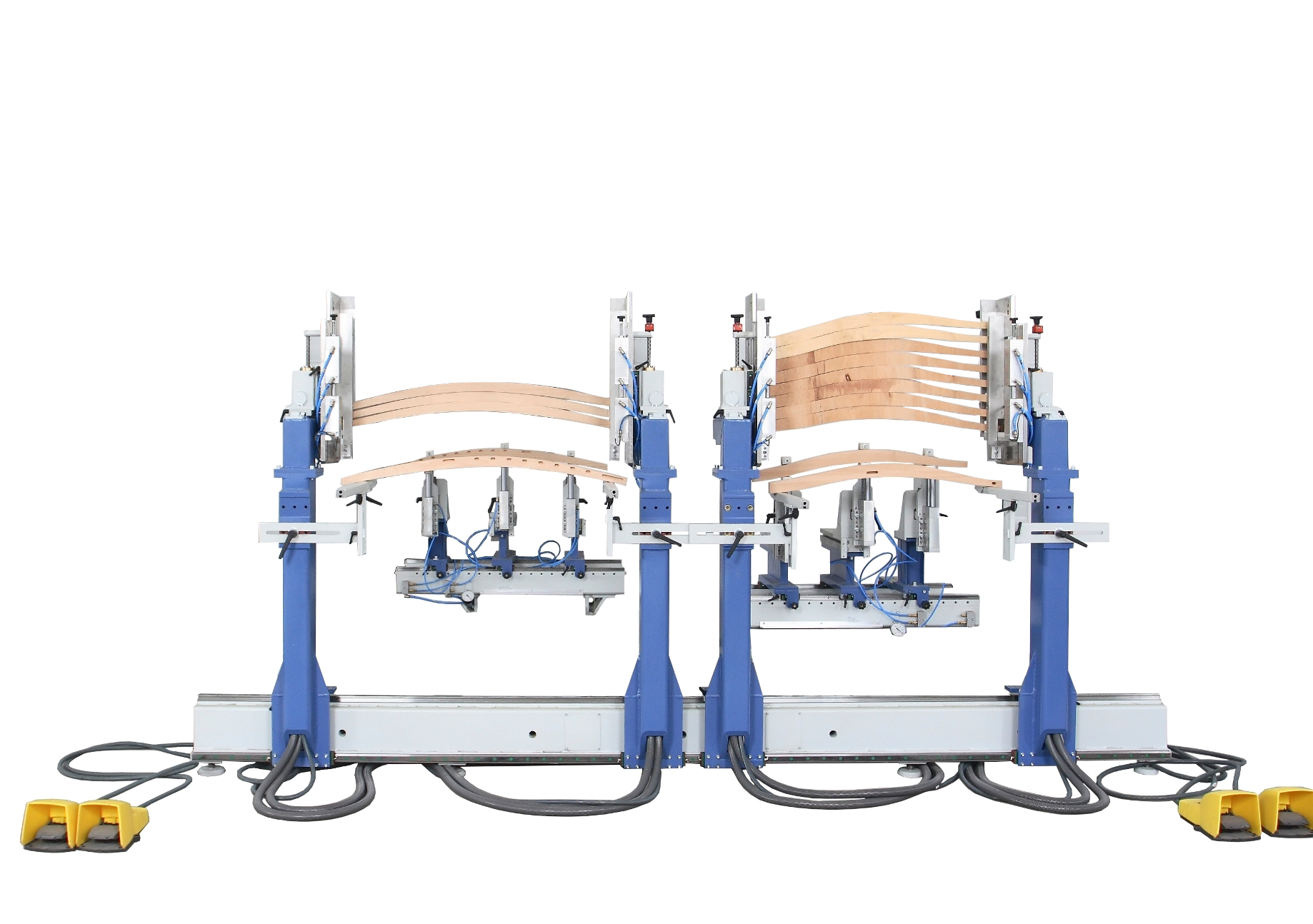

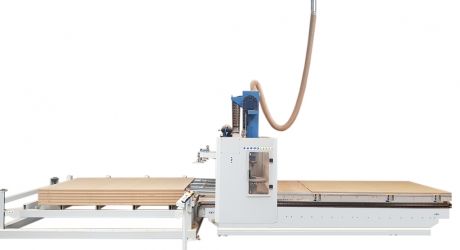

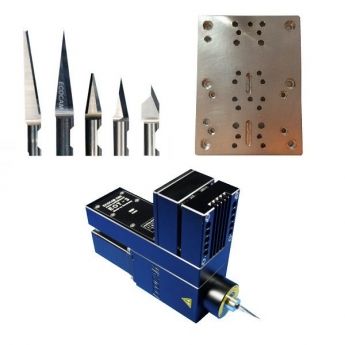

Automatic element storage - pneumatic ZM grippers

Workpiece feeder

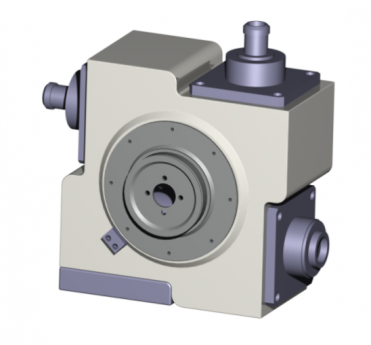

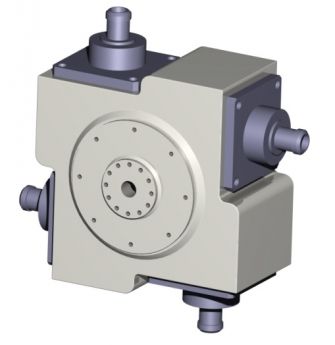

Automatic element storage - ZM grippers - pneumatic grippers mounted on consoles. The ZM type tray used in the cnc machining center with two working fields allows for unprecedented efficiency in the alternating machining mode.

Forget about wasting machine time unloading and loading parts!

The construction of the container allows for the automatic transfer of the finished detail and the collection of the prefabricated element from the feeder on one support while processing is taking place on the other. After the last operation on the element from the left table, the machining head has the workpiece from the right table at its disposal immediately in its work zone, so the machine work pace is limited only by the maximum possible machining parameters resulting from the tool design. The effect of using such a solution is the shortest time among machines of this type between the end of the machining of the first detail and the start of the next machining - less than 2 seconds!

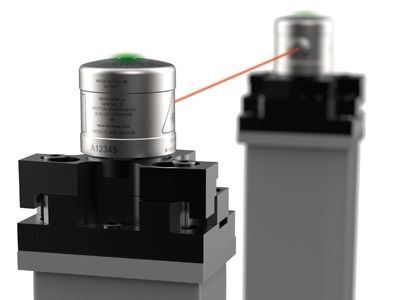

The ZM element hopper has a patented design with an anti-collision system.

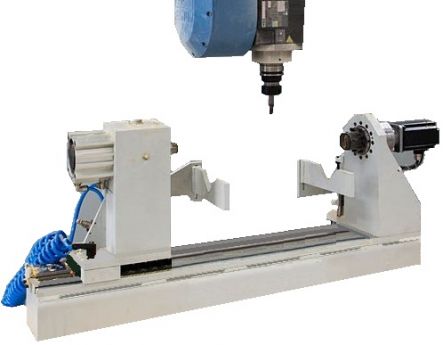

- pneumatic clamps, ZM type

- adjustable position (in three directions - X, Y and Z)

- adjustable opening (depending on the thickness of the element),

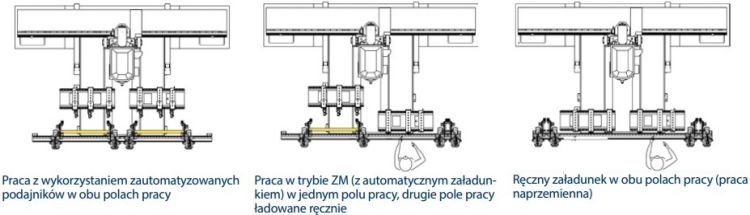

Work modes of the workpiece storage

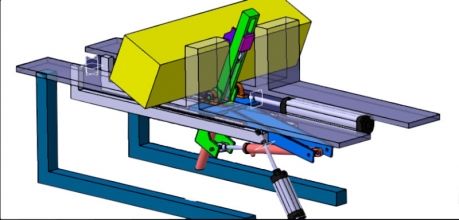

The structure of the magazine allows, depending on the needs, to perform work in an automatic, semi-automatic way and with manual loading and unloading of workpieces (see illustration below).

- ZM mode - work in an automatic and semi-automatic cycle with the use of automatic feeders in both fields.

Automatic work with the use of automated feeders in both fields of work. The operator puts the elements into the magazine, from where they are individually picked up by pneumatic grippers mounted on the work table consoles. The workpieces remain clamped until the end of the machining cycle. After machining, the elements are sent to the lower, receiving part of the magazine. Semi-automatic work - in one field of work, the other field is loaded manually. - Work with manual operation

Manual loading in both work fields (alternate work). In the event that it is not possible to use an automatic magazine (e.g. when processing elements that cannot be clamped in standard pneumatic clamps), the elements to be processed can be placed manually on the work table. The magazine columns are easily moved to the sides in this case. Depending on the dimensions and shape of the workpieces, it is possible to use other clamping systems (e.g. vacuum, manual clamps, etc.).

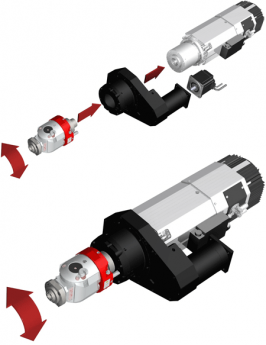

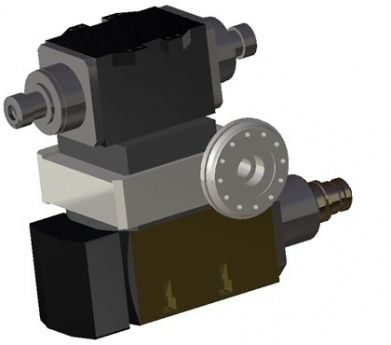

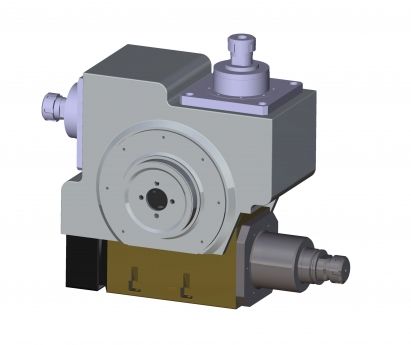

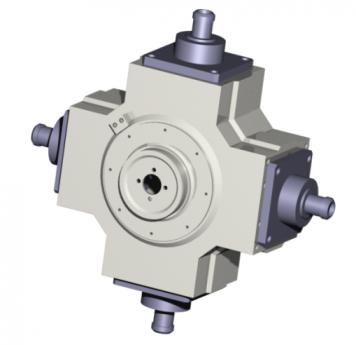

Automated cycle of workpiece gripper setting

ZM has a patented automatic gripper positioning system that allows for quick and precise setting of the machine to each detail, even bent in two planes!

It is possible to load items manually, without taking up space by the front magazine, which can be "parked" on the sides of the machine.

The machine tool can also be connected to the robot and work with it in an oscillating manner. Instead of the operator, the robot can feed workpieces or, in a continuous system, pick up workpieces on the other side. In such a system, the machine takes the material itself for processing, and the robot puts the elements back.