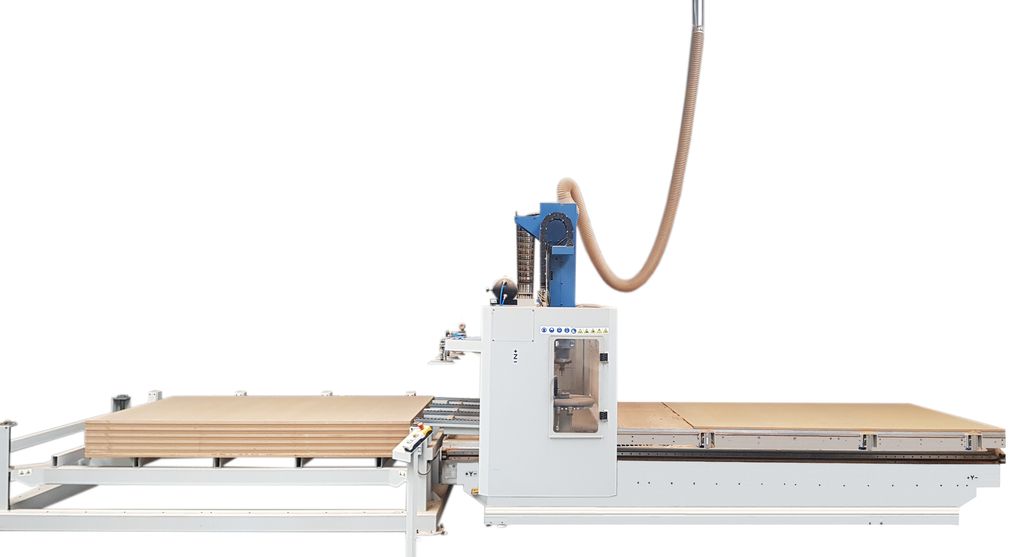

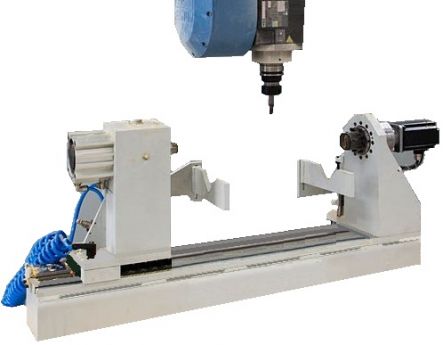

Automatic board feeding system to the router, CNC machining center

The automatic plate feeding system is a transport system that is used to automatically deliver parts to the processing process. It is dedicated to loading the board onto the working field of a cnc machine tool without the physical participation of the operator. The automatic warehouse of furniture boards can store the entire pallet of boards at a time. It supports both wood-based raw materials and industrial conglomerates.

The use of an automatic plate feeding system in the plant definitely influences the optimization of employment and production costs.

It allows you to automate the process of cutting, cutting, drilling and milling furniture elements. The use of automatic plate feeding is also important in eliminating human error and accidental damage to the plates during their transfer for processing.

.

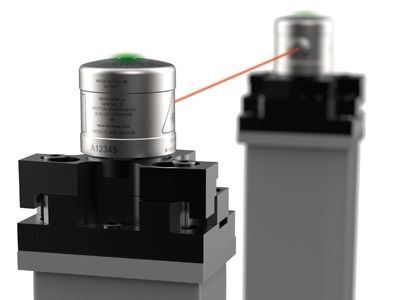

Automatic positioning

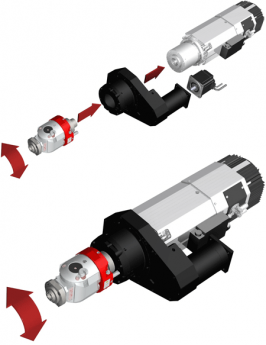

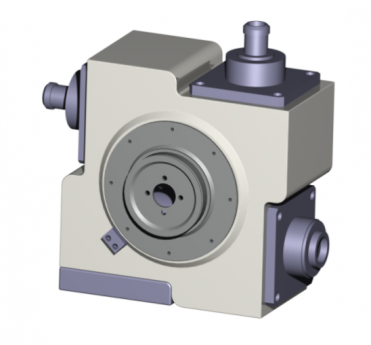

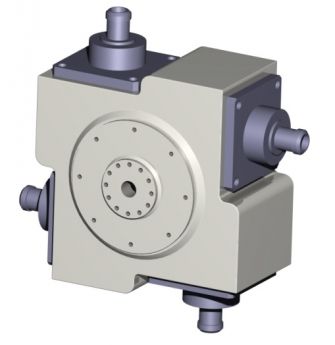

Automatic positioning of the plate on the working field of the machine tool is ensured by pneumatic mechanical bases, which allow for precise and repeatable basing of the entire plate format as well as smaller formats (e.g. plywood).

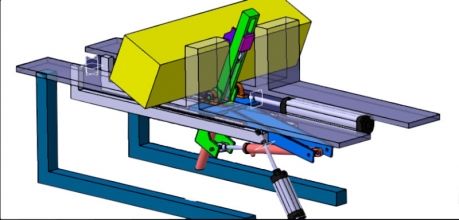

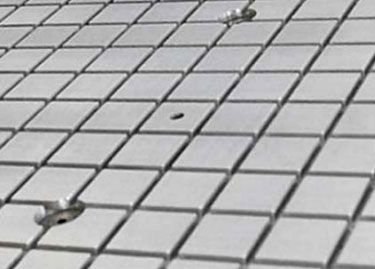

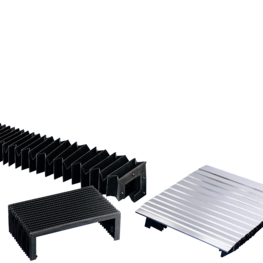

Vacuum and material clamping on the working field

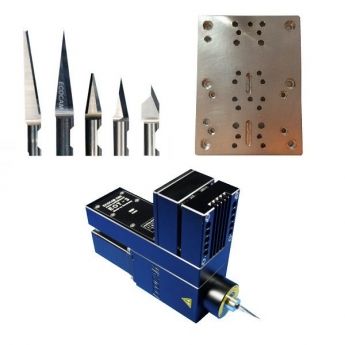

The processing center for nesting panels from the Trio and Sigma L series with a working area with a raster structure allows you to evenly distribute the vacuum over the entire surface of the table. As a standard, the table is divided into 6 vacuum zones controlled by electrovalves, which guarantees a secure fixing of the material on the table of the cnc machine tool. For customers who have various plate formats, it is possible to adjust the vacuum zones to the customer. Thanks to this, it will be possible to attach smaller board formats.

Receiving table for ready items

The optional receiving table for ready-made elements affects the work efficiency and speeds up the production process. During the next machining cycle of the machine, the operator has time to collect ready-made elements.

CNC technology allows for optimal adjustment of the machine to the specific needs of a given carpentry workshop. Nesting machines in service facilities are increasingly becoming an alternative to a panel saw and console CNC machining centers. It is an optimal solution for both the manufacturer of upholstered and box furniture. An investment in a machine with an raster table allows the continuation of the current production and opens up new, wider possibilities.

In nesting, apart from milling the shape, vertical drilling is often performed. In the furniture industry, the most frequently processed materials are: laminated and raw chipboard, MDF board and plywood. The technology is most often used in the production of: furniture fronts, structural elements of upholstered furniture, small and large elements of complex shape (puzzles, children's furniture, office tops) and furniture bodies.

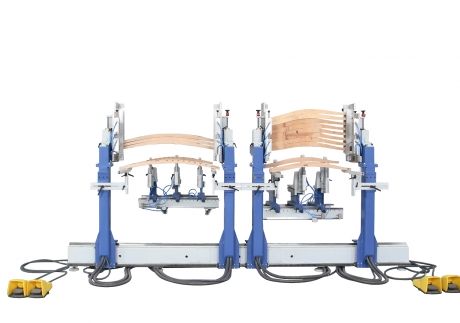

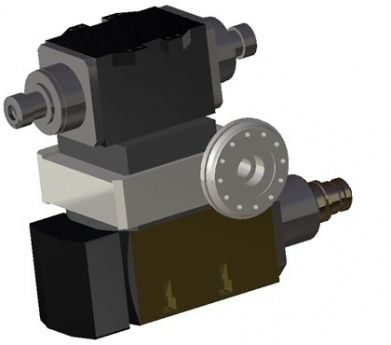

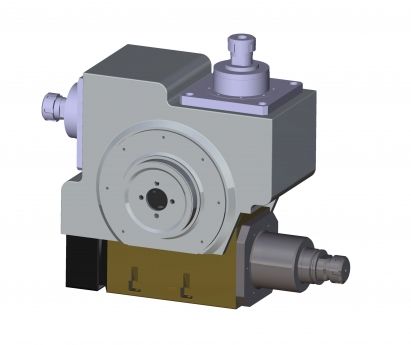

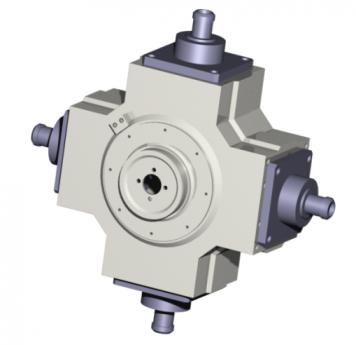

We design and manufacture loading and unloading systems with the use of robots. For special applications, FANUM offers robotic cells with loading and unloading manipulators with specialized mechanical or vacuum grippers, adapted to a specific task. Automatic loading and unloading systems in conjunction with appropriate accessories standardize the process, increase work ergonomics and efficiency.

FANUM CNC Machining center plotter with automatic loading of the furniture board