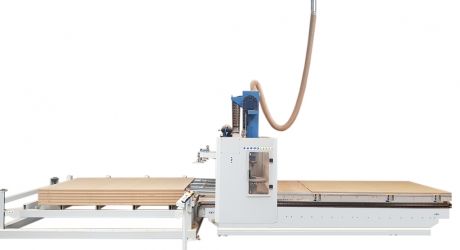

Central lubrication system in FANUM CNC machines

Automatic lubrication of the CNC machine

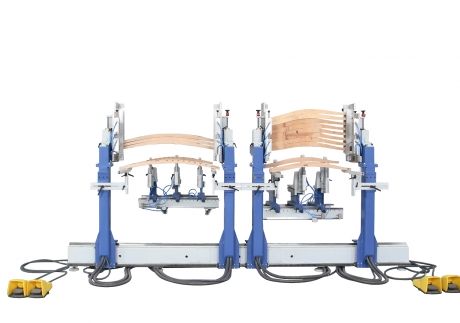

The central lubrication system guarantees precise and regular dosing of the lubricant at specific points in the cnc machine. The variety of types of central lubrication systems available on the market allows for optimal adaptation of the solution to the needs of a given machine. It is used in many industries, including metalworking, wood (lubrication of CNC machine tools).

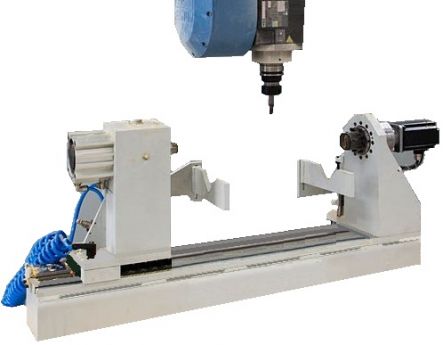

Progressive machine lubrication systems

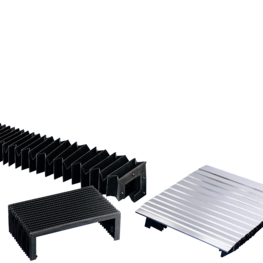

Progressive systems are used when there is a large number (in the order of several hundred) of lubrication points on a small surface. They are especially useful in the case of machines and devices with low or medium demand for lubricant. They can work continuously or periodically. They are supplied from a pump to which progressive distributors are connected. The most common is an electric pump, but wherever there is no possibility of connecting the supply voltage, pneumatic or manual pumps are used. Advantages of a central, progressive lubrication system

• low costs • simple structure and operation • possibility of expansion • low sensitivity to temperature changes • precise dosing of the lubricant • reliability and auto-control of the system (signaling of malfunctions, low level of lubricant in the tank)

How the central-progressive lubrication system works?

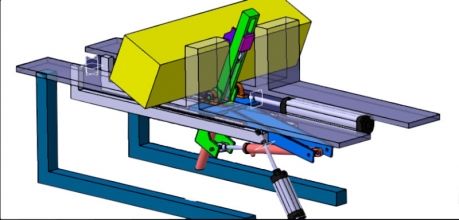

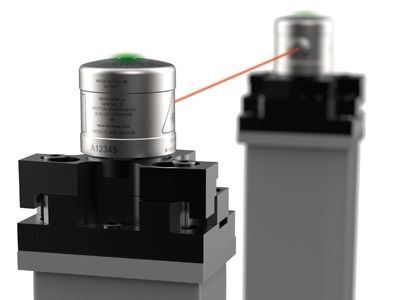

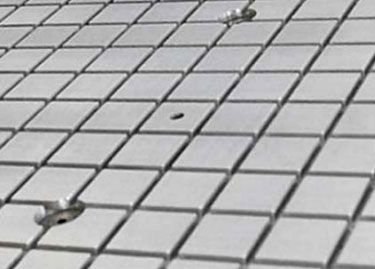

The central, progressive lubrication system differs from standard systems in that special adjustable manifolds are installed at its branches. These manifolds enable precise setting of the optimal, for a given point, amount of lubricant, regardless of the distance from the pump it is located. In this way, differences in the lubricant flow resistance, depending on the length of the lines, are eliminated. The lubricant is fed from the reservoir automatically via lines to the right places by means of a pump controlled by a numerical controller. At intervals specified in the program, an impulse from the controller causes the delivery of an appropriate dose of oil to all moving parts of the machine. The oil level in the tank is controlled by a sensor which, in the event of a level drop below a certain minimum value, displays a message on the controller screen about the need to refill the lubricant.

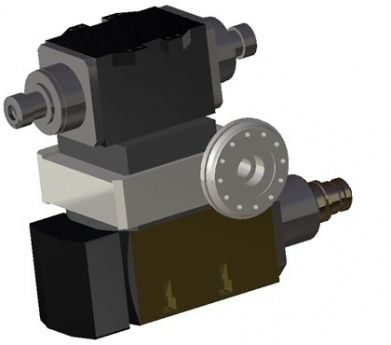

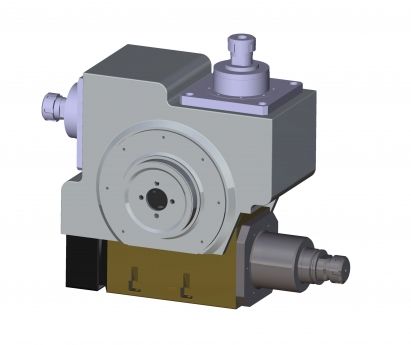

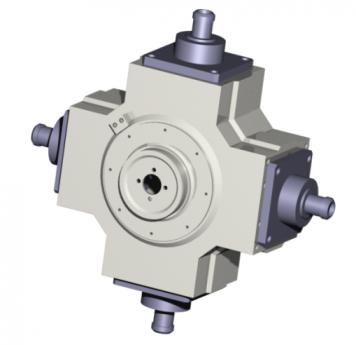

ILC MAX Pump Components:

1 - Tank

2 - Pumping element

3 - Electrical connector for input signal

4 - Power connector, output signals

5 - Grease nipple for filling the pump

6 - Controller with display

7 - Plug of the seat of the pumping element, return line or quick coupler for pump filling