CNC machine covers on individual order

CNC machine safety fence

Safety fence, machine enclosure is the most effective and simple way to fence off a danger zone. The need to ensure the safety of cnc operators and others is a decisive factor in the installation of a security fence. However, it should be remembered that production in the fenced-off zone should also run smoothly.

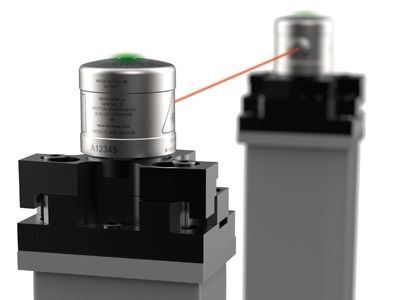

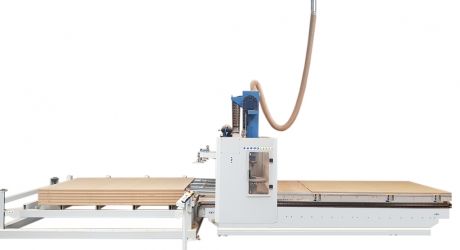

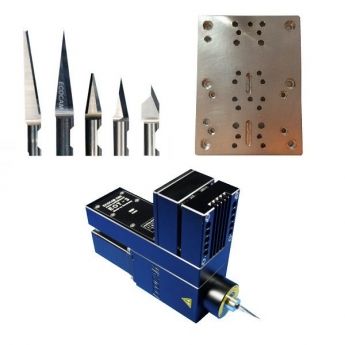

High speeds, fast machining cycles, coolant, dust and chips: running CNC machines are a dangerous environment for humans. That is why all machines: plotters, milling machines, FANUM machining centers are enclosed in almost impenetrable casings. Each machine manufactured by us has a CE certificate, which means that it has a number of safeguards to ensure full protection during operation. The closed, dustproof working space provides excellent conditions for efficient work with dusty and corrosive materials.

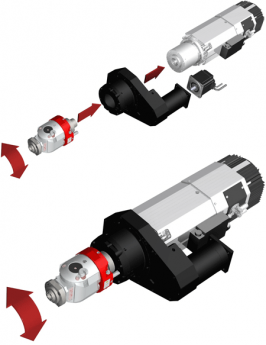

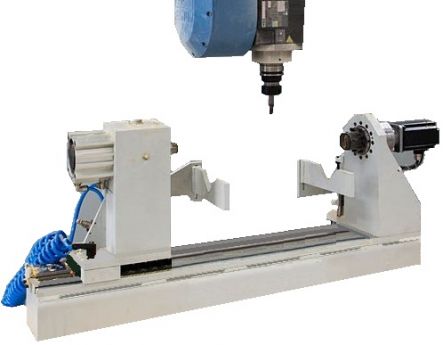

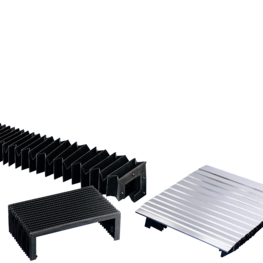

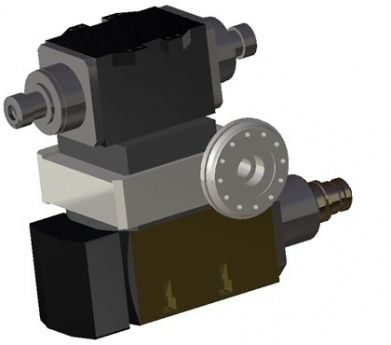

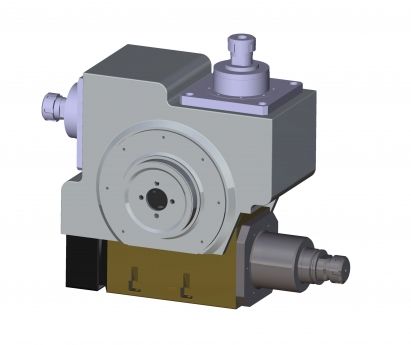

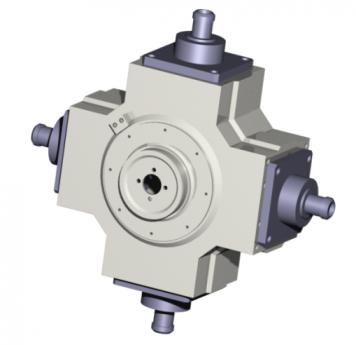

The structure ensures full safety during operation - it covers the moving parts of the machines (guides, toothed bars, milling heads), protects against the escape of e.g. chips generated during processing and harmful dusts. The enclosures of the machines also protect against the ingress of contaminants into its interior (important e.g. in the food industry), barriers against the entry of people in its vicinity (use of locks) and, if necessary, ensure the stoppage of the machine (use of limit switches).

Complete protective housing for a CNC machine

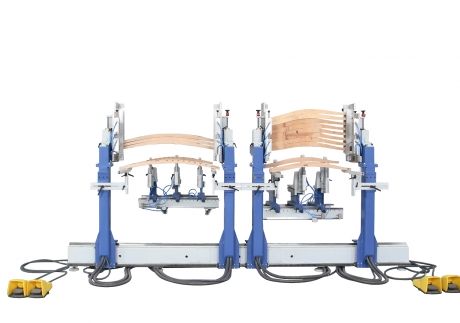

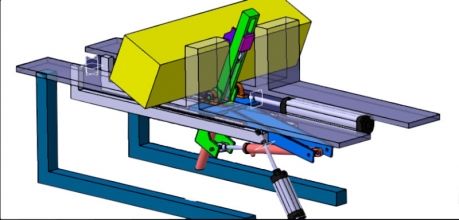

The surest way to secure the operation of the machine is to fully build it with a roof. The complete isolation of the operator from the machining zone gives 100% certainty that there is no risk from moving machine supports, working tools or chips. An additional advantage of this solution is the possibility of sealing the housing in order to provide anti-dust protection for the production hall. Fully built-up machines also enable acoustic isolation of the room from noise sources in the hall, but also vice versa - silencing the hall by isolating the most noisy machines - e.g. compressors, extractors in separate rooms.

The proposed solutions may have sliding or tilt doors and practically any shape (adapted to the nature of the machine's work). The door is protected against opening by appropriately selected safety switches connected to the safety system of the machine under cover. This allows the operator risk to be reduced or eliminated.

To enable the machine to be used to process a larger number of smaller-sized items, the machine casing may be provided with a loading door at both ends of the casing and in the side walls, and the working space may be further divided by internal, openable and removable partitions into several treatment zones. In order to ensure the required working conditions, in the case of processing very dusty materials, the machines can be equipped with a complete casing with a fixed or folding roof (folding type) that moves with the machine bridge. The use of divided loading doors and a safety partition enable very efficient alternating work on two working fields. In conjunction with the complete development of the processing area, the cleanliness of the production hall is maintained, even when processing dusty materials.

Extremely durable modular walls are created with the use of screws and rivets, as well as "sandwich" technology, without welded joints of prefabricated elements. Wall elements are normally mounted vertically on U-profiles, e.g. to the floor of a production hall. You can compensate for unevenness in the floor surface by adjusting it.

The housings are made of durable aluminum profiles and panels with permanent connections, and at the same time allow for easy disassembly and reassembly if the machine needs to be moved. We adjust the shapes and sizes individually to the dimensions of the ordered machine. The enclosures can be fitted with doors and inspection windows. For greater stability, the structures are usually attached to the ground on steel feet.

The structure is filled with: transparent plastics, polycarbonates, the so-called plexiglass, or toughened glass, etc. We take into account various possibilities of access to devices: latches, hinges, locks, blinds. The range is completed by doors and gates. Depending on the needs, we offer buildings and fences with the following filling:

- plexiglass plates,

- polycarbonate sheets,

- PVC plates,

- perforated sheets,

- corrugated mesh,

- protective panes,

- other.