Oil mist for cooling and lubrication of CNC tool

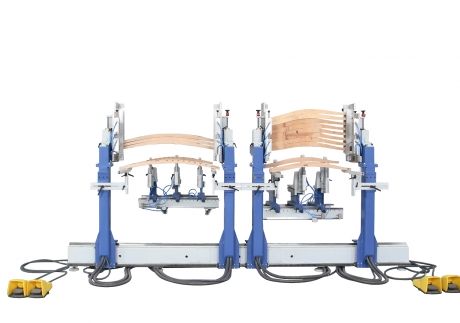

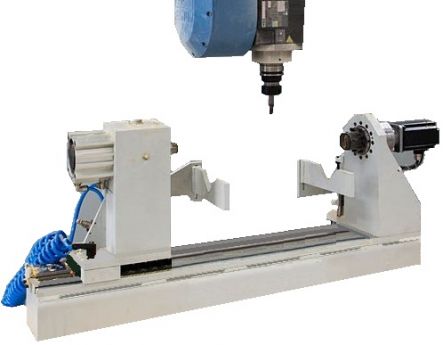

CNC tool cooling system with oil mist is a machining with minimal MMS / MQL cooling and lubrication. Oil mist is usually applied to the contact points of the tool and the workpiece during cutting, milling, drilling, reaming or threading. It also works well in situations involving the supply of oil to rolling bearings, e.g. in spindles. It is a good alternative for dry machining (no coolant) and for cooling and emulsion lubrication. Especially in plants specializing in large-scale machining.

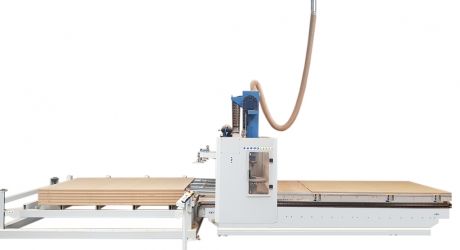

The oil mist cooling system replaces the traditional, low-cost cooling systems based on emulsion solutions. This system is used primarily for cooling tools in machines for cutting and processing metal, wood and plastics. Machining at higher speeds and the hardness of the material being processed increases the amount of heat, and therefore also the need for coolant. In this situation, the use of a cooling lubricant in large-scale production ceases to pay off. This system reduces machining costs and increases machining efficiency compared to traditional methods, provided that optimal cutting conditions are ensured. Also:

- reduces coolant consumption (does not adversely affect the quality of the material produced),

- extends the service life of cutting tools.

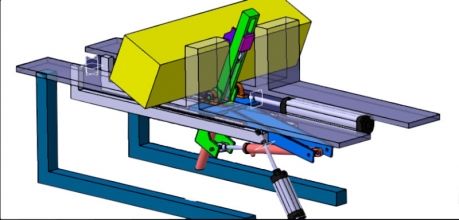

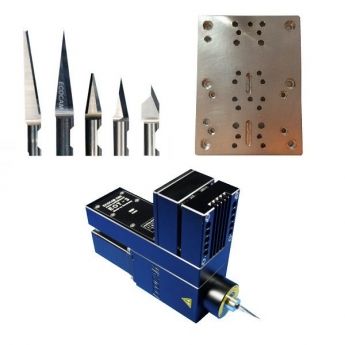

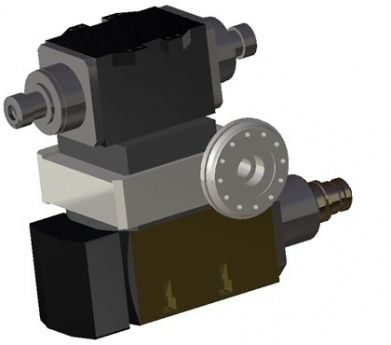

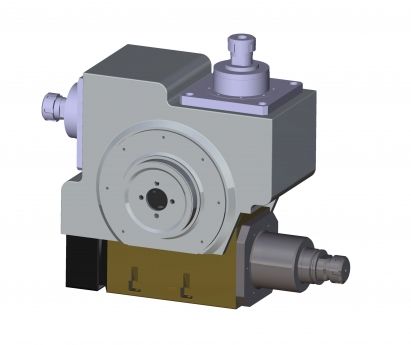

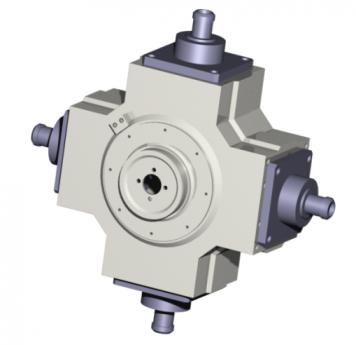

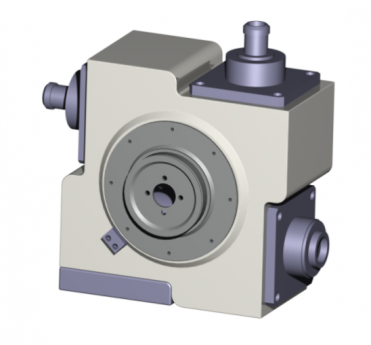

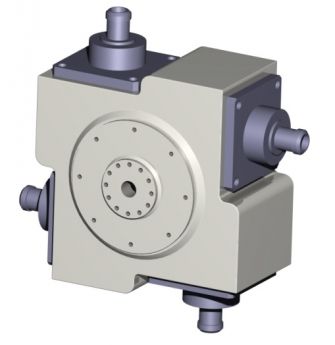

Oil mist cooling system includes:

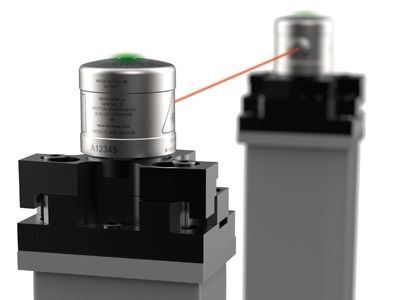

- oil tank with pneumatic pressure system

- regulating valve

- installation

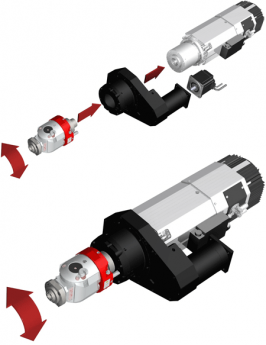

- spray nozzle.