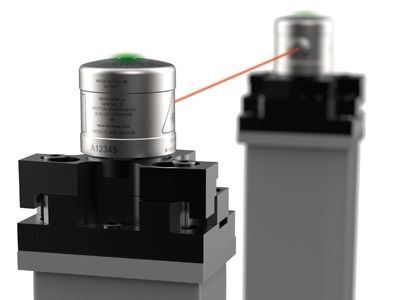

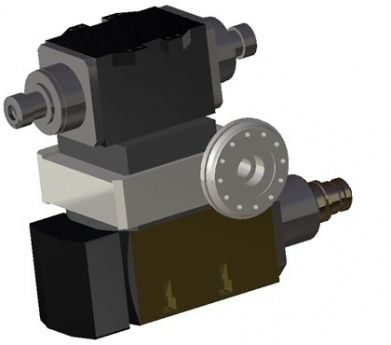

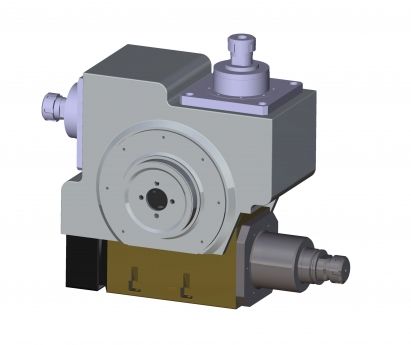

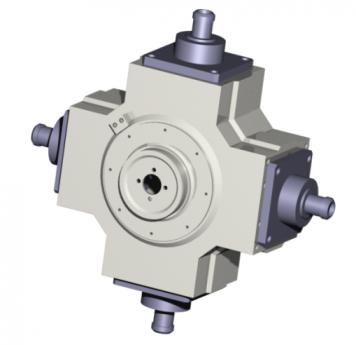

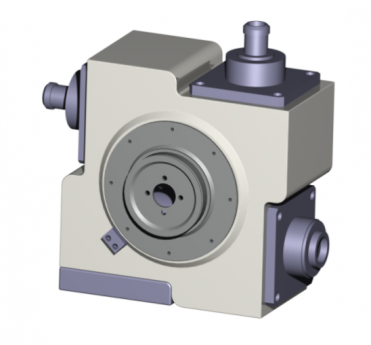

Pneumatic oscillating head with the oscillating knife EOT-3

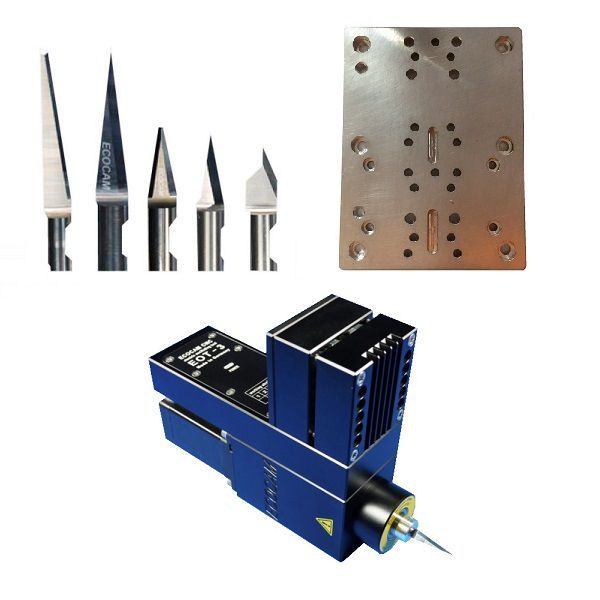

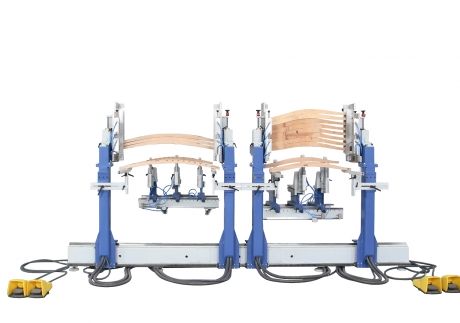

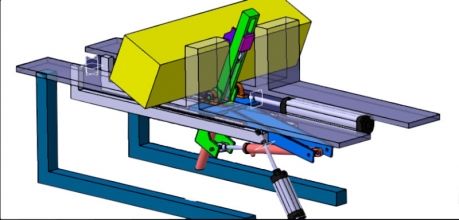

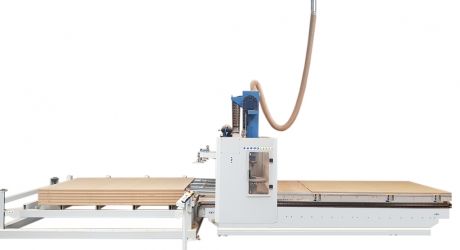

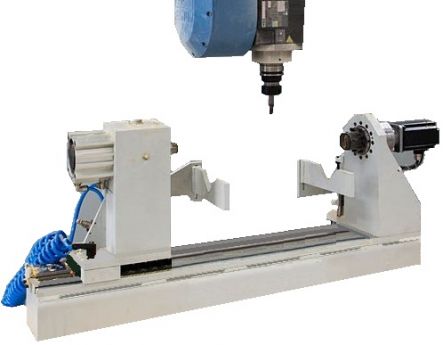

CNC head with oscillating knife EOT-3 for CNC machines for cutting materials. Especially suitable for precision cutting of leather, cardboard, cork and thick foams, sealing materials, foils, carbon fiber prepreg, rigid foam and much more. The powerful oscillating motor quickly moves the blade up and down while the actuator rotates the blade in each direction of the cut. As a result, even strong and thick materials can be cut precisely and quickly. As these modules have an open interface, they can easily be combined with systems from different machine manufacturers.

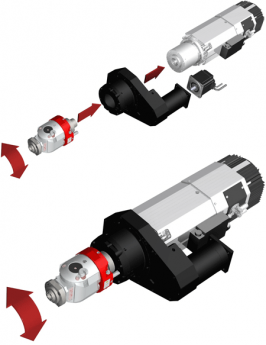

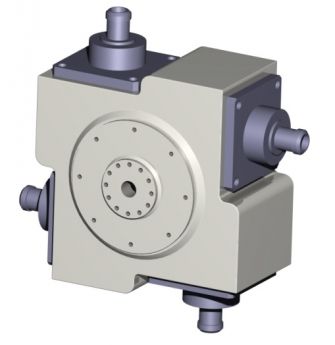

The EOT-3 head is the successor of the EOT-2. The most important improvement concerns the kinematic system of the tangential axis of the oscillation. Axial, radial and torsional stiffness as well as wear resistance are optimized. The external dimensions and attachment points have not changed, the integrated new electronic system is compatible with the previous one, and all accessories and blades are compatible with the new system.

Construction of the head:

- Manufactured in CNC technology, solid, all-metal housing for optimal vibration damping

- Precision ground kinematics for enduring precision.

- Drive motor with multiple ball bearings

- Optoelectronic, non-contact and wear-free blade position detection

- Seamless connection with systems from different manufacturers

The use of an oscillating knife head

Sealing materials - Carbon fiber prepregs - Corrugated cardboard / hard cardboard - Leather and cork - Fabrics and foils - Rigid foam pastes - Carpets - Insulating materials - RUBBER