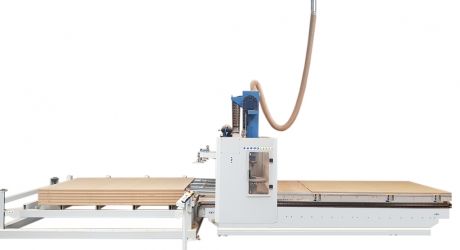

Beam table for CNC machine

Consoles for stairs, windows, doors

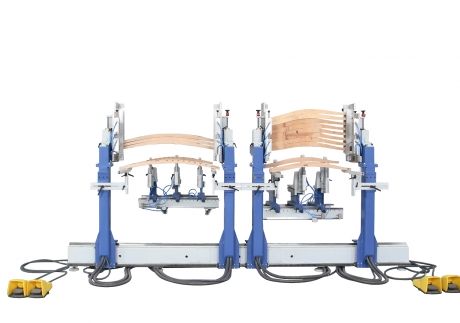

Beam table also known as a traverse or console table. The most common purpose of this type of tables is the processing of boards, solid wood, window and door joinery. This table is made up of independently shifted beams in the Y axis (traverses, consoles). In these beams there are integrated - one or two vacuum circuits - which ensure that the vacuum is supplied to the CNC suction cups (vacuum blocks). Beam tables allow free positioning of the suction cups along each beam (in the X axis).

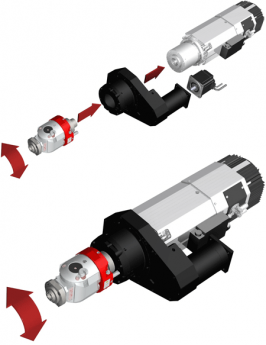

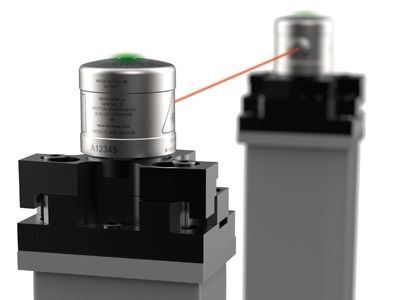

Depending on whether the beam table is single-circuit or double-circuit - the suction cups are attached to the beams mechanically or under vacuum. Suction cups (vacuum blocks) ensure the fixation of the elements during processing. Beam vacuum tables also allow the use of mechanical clamps supplied with vacuum or compressed air. CNC mechanical clamps are most often used for solid wood processing, e.g. for the production of windows or stairs.

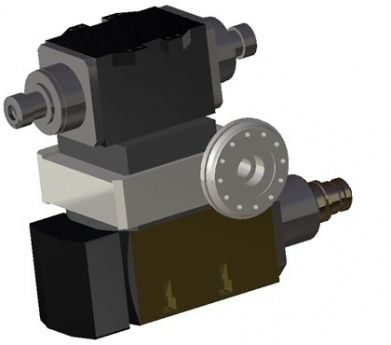

Offered consoles - beam tables for manual positioning and setting of suction cups in FANUM machining centers:

- FANUM FK consoles - solid and stiff, steel FK consoles designed for the toughest jobs. T-slots in the side planes of the beams allow for secure mounting of clamps, clamps or pneumatic grippers. Fanum beams are also available with wooden inserts - practical and ergonomic loading consoles, positioned along the machine table.

- Schmalz consoles - vacuum, dual-circuit beam tables allow mounting clamps and vacuum suction cups. The system allows for quick and reliable gripping of the workpiece during processing.

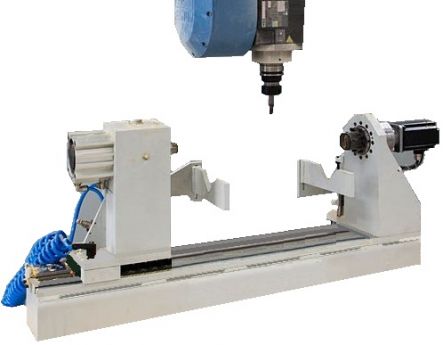

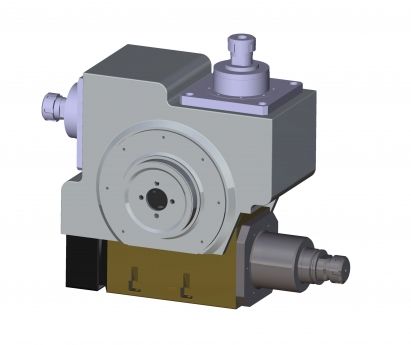

NC controlled beam work tables

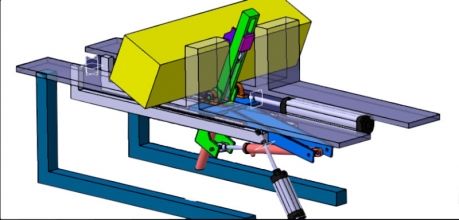

The work tables with automatically positioned beams (NC-controlled) are an option that allows interpolated movement of the loading consoles on the work table, in order to enable machining of workpieces with complex shapes. It is also an excellent solution when milling two symmetrical workpieces.

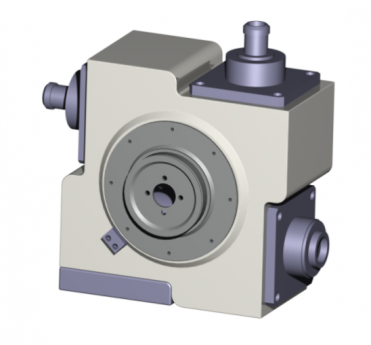

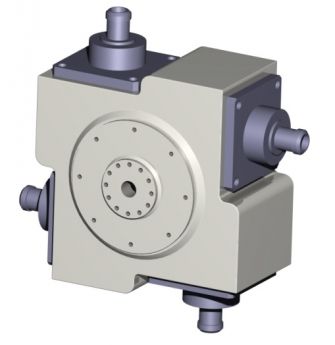

Templates or other tooling and workpieces are clamped to the beams mounted on the tables. Each table is equipped with two beams. One beam is a fixed beam, while the second beam can be moved along the table by servomotor. The movable beam is numerically controlled NC with software dedicated to the machine. The control of the beams takes place by entering the position of the moving beam into the software.

The advantage of this solution is the simultaneous machining of two symmetrical pieces on one table, which in practice gives the efficiency of the manufactured piece with two-table machining.

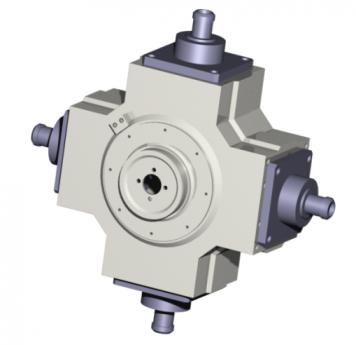

- 2 stoły robocze napędzane seromotorami

- tryb pracy stołów naprzemienny lub jednoczesny równoległy - "tandem"

- dodatkowe pneumatyczne elementy mocujące do mocowania elementów graniakowych.