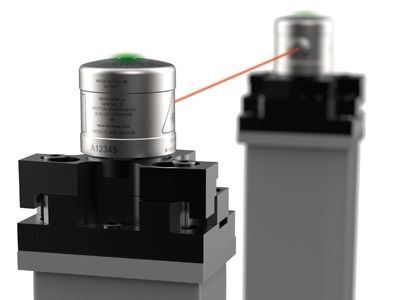

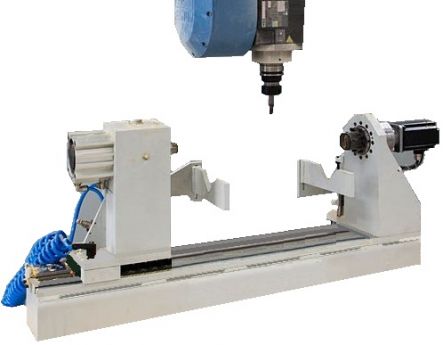

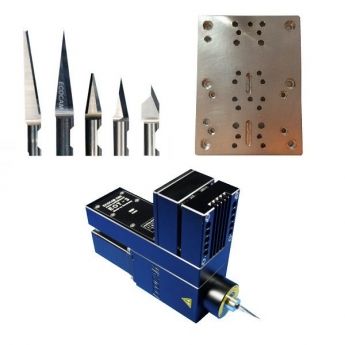

Contact probes stylus tips for CNC machine tools

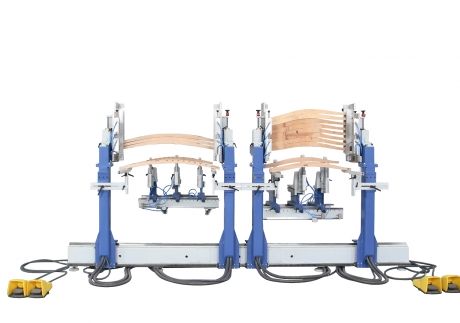

Stylus tips of the contact probes for a CNC machine tool provide the user with high precision of measurements, e.g. when checking turbine blades.

Stylus for precise measurements

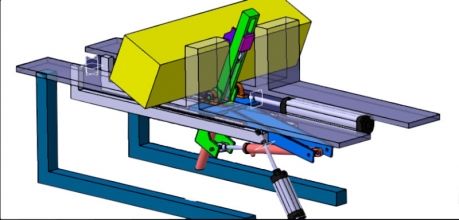

Successful measurement depends largely on the ability of the test probe to reach the item being measured and maintain accuracy at the point of contact. In any case, the key is the maximum stiffness of the stylus and the perfect sphericality of the tip.

Due to the increase in quality assurance standards in recent years, in order for companies to remain competitive, they have to provide first-class process stability and the highest quality measurements.

Applications of styli

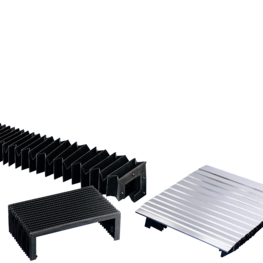

The straight measuring tip is used to measure simple elements that can make direct and undisturbed contact with the surface to be measured. The carbon fiber shaft is lightweight and is the ideal solution where weight is not a decisive factor.

Ruby is the standard stylus tip material in the metrology industry. It is one of the hardest materials and is suitable for most applications. Due to its attracting properties, it is not recommended to scan aluminum parts.

At a basic level, the arbor selection always refers to the connecting thread of the CMM sensor - typically M2, M3, M4, or M5.

We use Renishaw, which offers the widest range of styli and accessories:

- with all connecting threads,

- suitable for sensors and accessories from all manufacturers

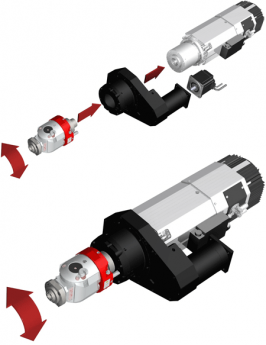

- also probe pins for CNC machine tools.

Measurement performance can easily be degraded if you use a stylus with poor ball roundness, wrong ball location, poor thread fit, or a damaged design.