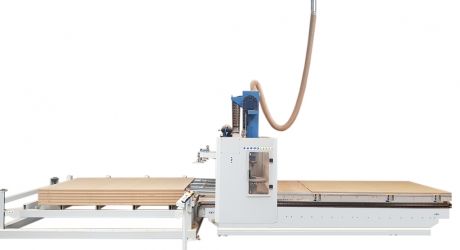

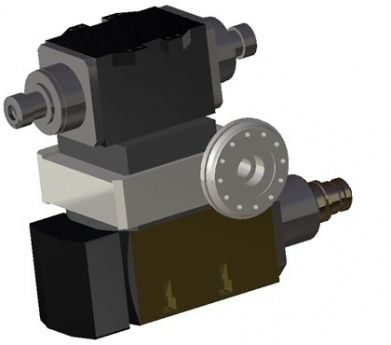

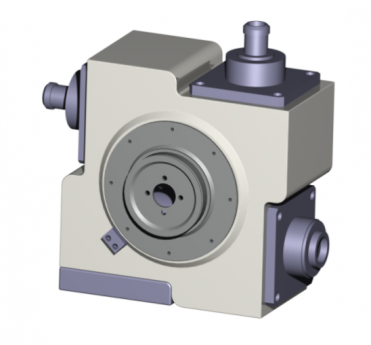

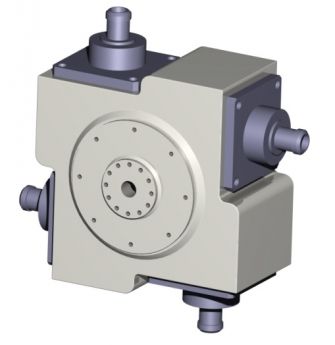

FANUM FDL1 tool length probe for CNC milling machine

The FDL1 probe is designed for automatic tool length measurement for numerical milling machines. Automating tool measurement allows you to significantly save time needed for tool change and measurement. It is also important to eliminate mistakes and inaccuracies when manually setting the zero point for the changed tools. When automatic tool measurement is used, the zero point for the Z axis is determined only once at the beginning, and during subsequent machining steps and tool changes, the Z zero point is automatically recalculated. The control program corrects the coordinates depending on the measurement of the tool.

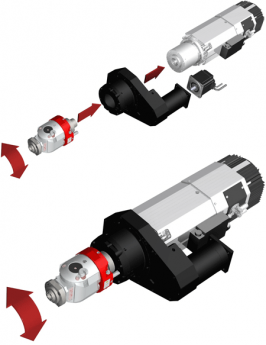

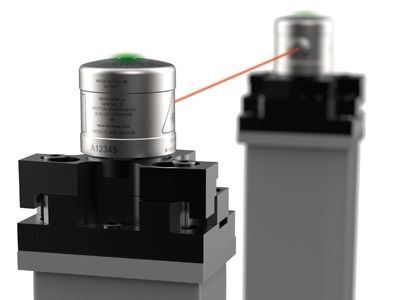

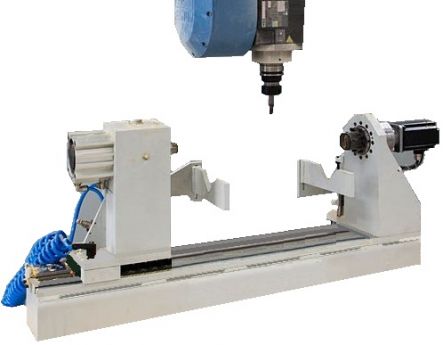

The tool probe is equipped with a dual sensor system. The first measuring stage is the actual measuring sensor, the next one is the safety sensor. The safety sensor can be used for emergency stopping the machine in the event of an uncontrolled run over the sensor. Such a situation may take place when the measurement of a tool longer than the declared measurement area is performed. The measuring area is the range within which the machine reaches the sensor at the measuring speed.

The method of taking the measurement can be performed on arrival and on departure. Proper measuring speed should not exceed 2mm / sec (recommended 1mm / sec). The measuring speed is the speed at which the supervisory system waits for a signal from the sensor. The most effective way is to program the departure measurement - the head with the tool approaches the sensor at the switching speed, reaching the measuring area, it is reduced to about 5-10 mm / sec. At this speed, the movement towards the sensor continues until the sensor is triggered. Then, at a speed of 1 mm / sec, the sensor is driven away. The moment of switching the sensor is the moment of recording the measurement by the supervisory system. Of course, all these operations are about Z-axis movements.

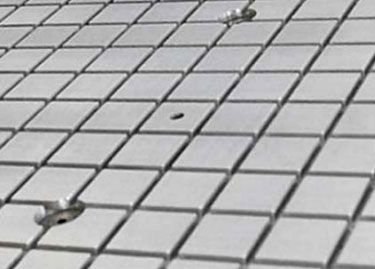

The probe is closed in a splash-proof metal housing. The bearings of the moving parts have seals. There is a vent at the bottom of the probe base. Fix the probe in such a place that the base is not exposed to submersion in the coolant. The design of the probe protects it against the effects of the cooling emulsion. However, do not direct liquid jets directly at the sensor.