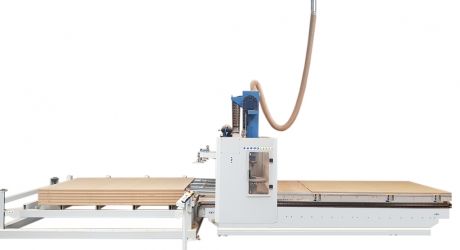

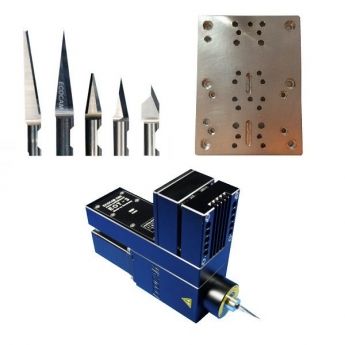

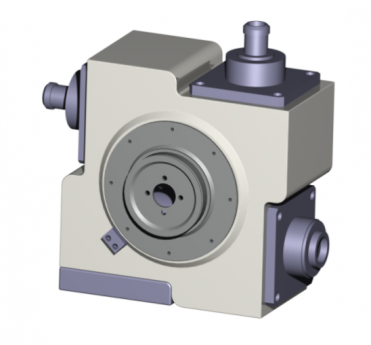

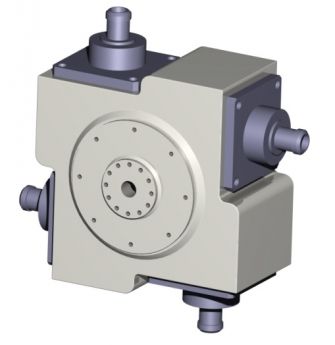

Vacuum raster working table for CNC machine

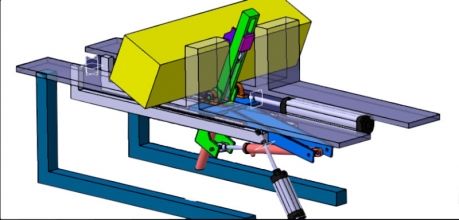

Vacuum raster table top for a cnc machine tool: a plotter or numerically controlled machining center is used for milling, cutting, cutting furniture boards, wood-based, flat plastic sheets, plywood, aluminum plates and sheets, building boards (HPL, Alucobond, Dibond, Plabond, Reynobond, Tubond, OSB chipboard, MDF, HDF, building boards, Corian). Products made of cut and milled boards in the CNC technology are, for example: facade panels, decorative panels, device housings, illuminated coffers, construction of exhibition stands and expositions, shop fittings, shop displays, advertising billboards, furniture fronts.

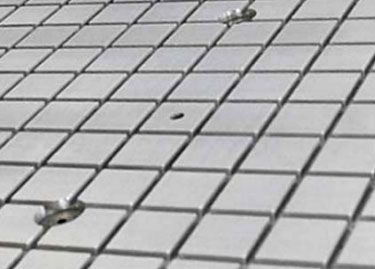

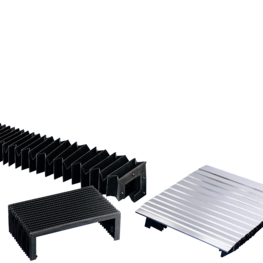

Vacuum raster tables are usually made of an aluminum solid plate, mounted on the machine bed, which is the basis of the work table. At the customer's request, the raster table for a plotter or a cnc machining center can be made of a cast iron top or a plywood board laminated with phenolic resins (HPL). Moreover, the table can be divided into several vacuum zones (sections) thanks to the use of an optional collector.

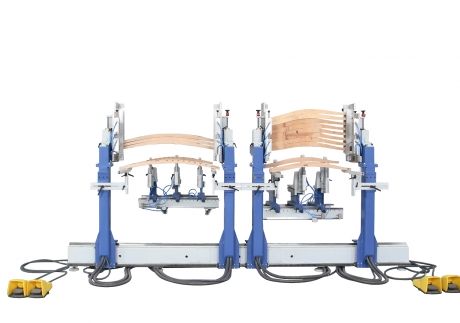

Sometimes, raster tables are mounted on existing tables, e.g. on T-slot tables or consoles (beam tables), in order to increase the machining capabilities of the machine tool.

Advantages of vacuum tables:

- full-surface and precise mounting of elements.

- precise adjustment of the suction surface to the fastened element.

- cutting large format boards (nesting)

Disadvantages of vacuum tables:

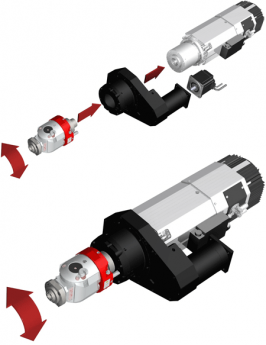

- formatting, frontal drilling and bottom-edge processing are possible only with the use of templates or suction cups,

- table conversion is time-consuming.