Safety elements of CNC machines

FANUM CNC machines are designed and constructed with the maximum safety of the CNC operator in mind, while maintaining the greatest possible CNC functionality.

Machine tools are delivered with safety devices compliant with the requirements of European safety standards (declaration of conformity with the relevant standards in force in the European Union "CE").

Safety covers

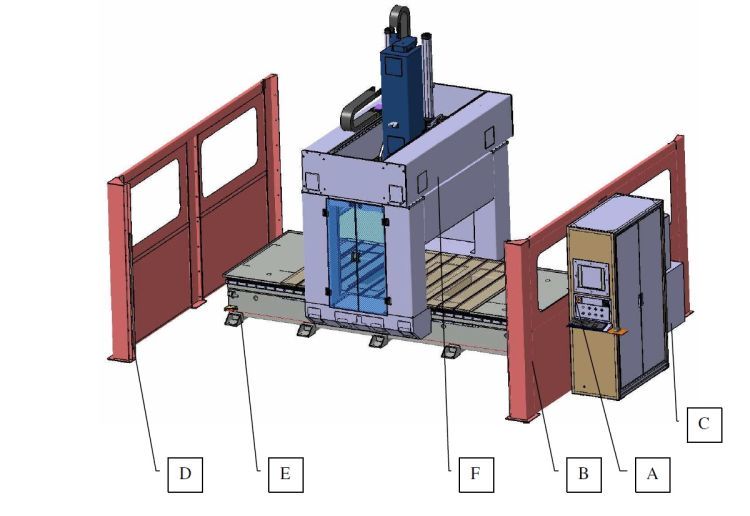

Each FANUM machining center is equipped with the necessary safety covers (B). These are mechanical protection of the CNC machine's work zones.

Safety covers are designed to protect the operator against sawdust and shavings, as well as to reduce noise and dust generated during the operation of the machine. They constitute a permanent barrier between the operator and particularly dangerous parts of the machine tool (head, portal).

- head cover, machine portal casing (F) - the sheet metal casing of supports serves to protect the operator against sawdust, shavings etc., to reduce the noise generated during machine operation and to partially separate particularly dangerous parts of the machine (head, spindle, tool) from the operator The cover is equipped with a hinged hatch enabling servicing related to the Y and Z axis supports and the machine head. The hatch is secured with a safety bolt switch, the use of which turns off the machine,

- peripheral protection - an external fence with a door for loading, for service and maintenance purposes, with a gate locked with a safety switch that turns off the machine. To prevent accidental access to the working area of the machine,

- protective screens - in cases where there is a risk of danger from chips, splinters,

- partition between work zones (in two-table machine tools of the Sigma series).

CNC machine tools security elements

A. Emergency switches (so-called mushrooms) - pressing the emergency switch immediately deactivates the machine. The buttons are located on the main operator panel on the control cabinet, the portable panel (remote control) and the front of the protective housing (easily accessible from the working place).

C. Cut-off valve - turning it, serves to protect the operator during service activities on the machine. It cuts off the supply of compressed air from the external network to the machine tool, thus blocking the lowering of all pneumatically driven elements.

D. Laser curtain / light barrier - it is a mechanism that prevents entry into the danger zone while the machine is working, and stops the device when the laser beam is exceeded. When the light beam is interrupted, the machine stops immediately. Entering the work area of the machine is possible only when the machine is turned off or in the manual mode.

E. The safety cord (cable switch) is stretched along the machine's worktable. Its use stops the machine. Before restarting the machine tool, make sure that the threat to the personnel, bystanders and the machine tool mechanisms is gone.

Foot Pressure Mats - foot pressure-sensitive safety devices signaling human presence in the machine's danger zone, are also used in the so-called zone work at the machine (stepping onto the mat triggers a movement or stop signal). Thanks to them, you can effectively avoid accidents at work or reduce them to a minimum.

Manufacturer of CNC machines - FANUM