CNC milling machine for styrodur

CNC machine for polystyrene, for polyurethane foam

A properly configured and equipped CNC machine can be used to machining various types of materials - aluminum, plastic, plexiglass, wood, etc.

- For CNC machining of a flat surface of styrodur, polystyrene, polyurethane foam, plotters are most often used, which are nothing but table-type milling machines.

- For the complex CNC milling of 3D models, cnc carving, you will need a 5-axis machine.

As with all machining processes, there are several factors to consider when selecting a material to be milled, such as material properties (i.e. hardness, tensile and shear strength, and chemical and temperature resistance). These criteria determine whether the material is suitable for the CNC milling process.

The selected raw material also determines what type of machine tool to use and the optimal settings for the machine and cutting tools.

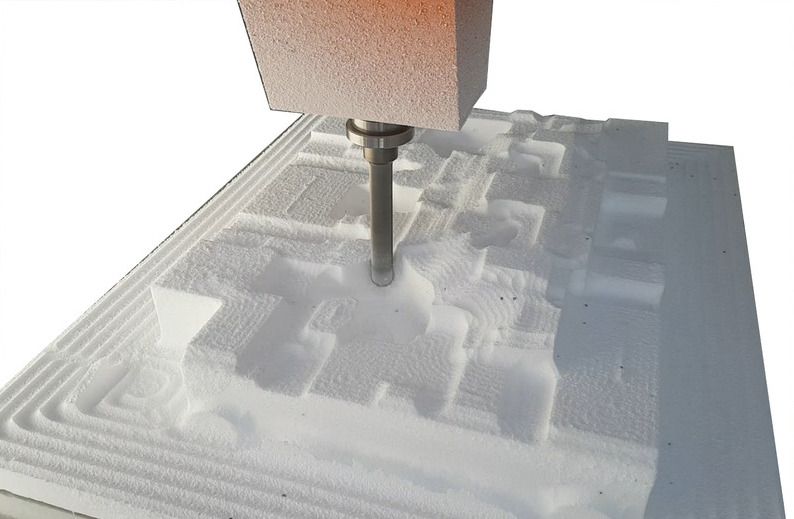

CNC cutting with a milling router

Where the limitations of CNC cutting with an oscillating knife prevent us from obtaining the proper effect (e.g. due to the height of the element being cut) - we can use the cutting technology using CNC milling.

Properly selected parameters of the machining process: cutting direction, feed, rotation and angle of entry into the material, so that the material does not heat up too much, will make the edges nice and sharp.

Milling foam

Milling of foams involves machining with a multi-blade tool. This technology is so developed that it allows to obtain even a very complicated product.

Our offer includes 3-axis machines that perform both simple 2D milling and 5-axis machines for advanced 3D machining.

Milling routers with an increased range of Z axis

FANUM milling plotters can optionally have a raised gate, increasing the working range of the Z axis (up to 700 mm). Equipping the plotter with a vacuum table enables quick and clean cutting of the material by sucking it to the raster table surface. This avoids mechanical fastening, which often causes damage or contamination of the cut material.

By using CNC head with an oscillating knife, we can cut when machining is not possible with cutters. The use of an oscillating knife enables cutting materials of considerable thickness.

Milling: XPS foam (letters, graphic elements), foam plates (PE plates, polyethylene plates), cutting letters from polystyrene or styrodur, tool inserts, filling for boxes, models for polystyrene casting, decorative foams, prototype elements.

The FANUM CNC machining center of the LAMBDA VT series, in a special 3-axis version, is designed for processing foam materials, hardened modeling paste, wood, plastics-based composites and elements made of aluminum and materials of similar hardness.

The design of the machine is characterized by great versatility and a large working space while maintaining a relatively small size of the machine.

The design of the machine is characterized by great versatility and a large working space while maintaining a relatively small size of the machine.

In addition, the ability to work in two independent work zones makes it possible to eliminate loading and unloading times of the detail, which significantly increases the efficiency of the machine.