Five-axis CNC Carpentry Center for CLT machining - ATLAS

Special CNC Carpentry Machine for the production of prefabricated wooden houses

CLT (cross-laminated timber), i.e. the production technology of panels made of cross-laminated solid wood. The main advantages of CLT and sister LVL technology (glued laminated veneer wood) are very high load capacity, dimensional stability, the possibility of panel prefabrication and a high degree of fire resistance.

The use of CNC ATLAS

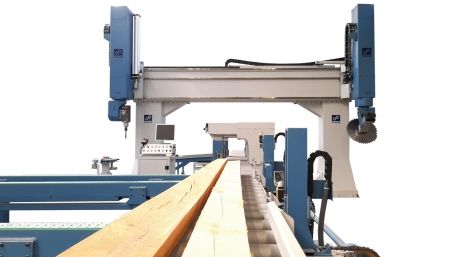

Atlas - CNC numerically controlled carpentry machining center equipped with 5 interpolated axes with a CNC machining design support system. Designed for the production of prefabricated (modular) houses, regardless of whether it is the production of wall elements, arches, roof structures (roof truss) or other large-size structural elements of halls, sheds and garden sheds.

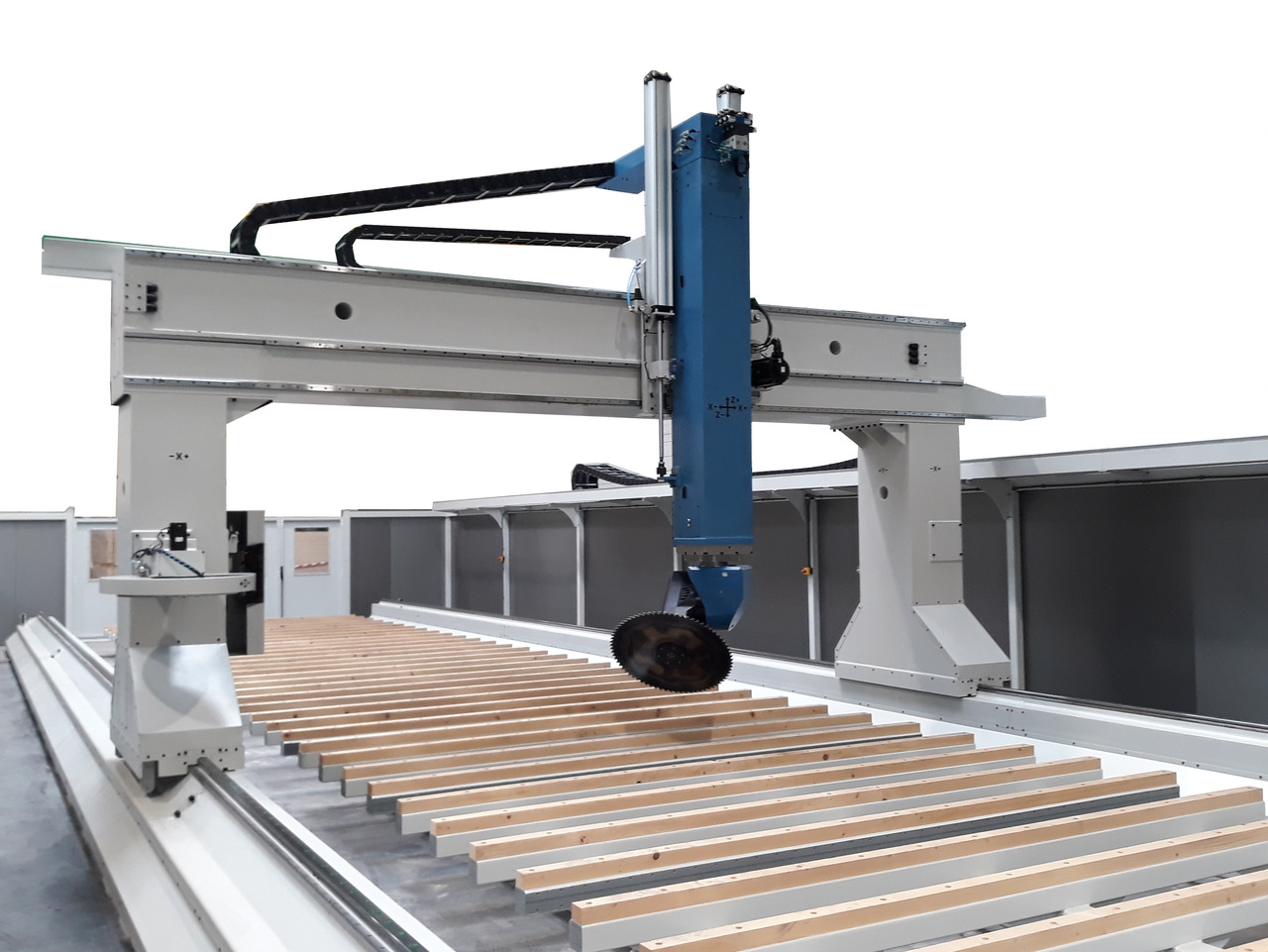

The Atlas is a perfect combination of the advantages of a portal structure with the versatility of a large work table. The standard table is an openwork steel structure anchored to the floor. Wooden inserts on the upper surface are a universal basis for processing heavy construction elements. The sides of the table have a network of threaded holes for attaching various types of suction cups, clamps or any accessories.

The huge, rigid gantry moves on a solid subgrade anchored to the hall floor. The ranges of the machine axis jumps are selected to machine most of the large-size structural elements used in five axes: main Y axis travel up to 31 meters. Transverse horizontal movement of the head 2.6-4.2 meters. In the Z axis, the machine has a range of motion of up to 1,300 millimeters. The working head is equipped with a 35 kW spindle with the possibility of automatic tool change in the HSK-A63 system from a 16-position revolver magazine or an additional saw socket with a diameter of up to 800 mm.

CNC Machining of five part sides in one clamping

The intention of the designers when building the discussed CNC carpentry machine was to achieve the greatest possible versatility. This special machine can process LVL or CLT panels with the maximum dimensions available. The processing of large-size arches made of glued laminated timber, the use for the production of joinery, stairs, curves, milling 3d models or wood carving confirm this idea. All this thanks to the technologically advanced working head with high power and torque of A and C axis drives. It is equipped with additional hydraulic brakes, thanks to which the rotary axes can be locked at any angle. This option is especially useful when machining with heavy tools such as saws or specialist heads. The compact design of the head, supported on one side, guarantees optimal access to the workpieces and the possibility of processing complex concave bodies, such as recently very fashionable wooden bathtubs, without having to remove and reload.

Machining (including milling, drilling, marking, tenoning) is carried out with the use of tools called aggregates mounted in the machining part. The basic tools are: a large diameter circular saw, end mill, large universal cutter and drill.

Excellent performance, unsurpassed quality

Atlas – multiaxes carpentry CNC machine, designed for machining of components of roof rafters, walls, bridges, construction arcs etc. made of solid wood, plywood or glulam, equipped with 5 interpolated axes. Atlas is innovative machine with portal construction and universal table.