Large-size CNC machining center - Lambda VTL

5-axis CNC millin machines for molds, forms and 3D models

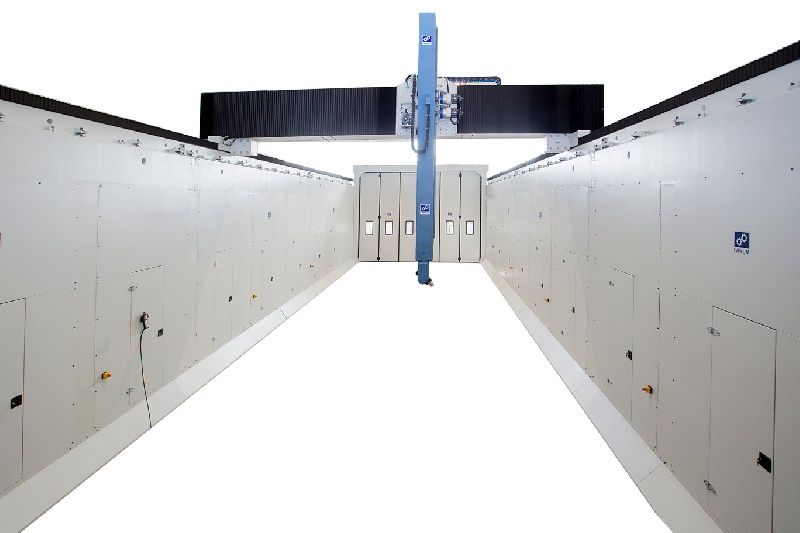

The design of the Lambda VTL CNC machine

Lambda VTL is a giant for special tasks with enormous potential. It is the largest among a series of five-axis machining centers, Best for machining elements, which require a large area of work while simultaneously maintaining high accuracy.

CNC Design

The structure of this specialized machine consists of two parallel rows of columns on which the spans are mounted, which are the basis of the track for the movable bridge. The bridge beam moves on appropriately sized rails and carries the column with a biaxial processing head. Both the bridge and the Z axis column are driven, each by means of two servo drives with a power appropriate to the weight of the system. As a result, the bridge movement is always perfectly parallel and the column is lifted by means of a rack gear, without the need for additional weight compensation components. As a result, the high quality of machining and the accuracy of workmanship are maintained uniformly throughout the huge working space of this milling machine. The standard equipment of the head is a milling electro-spindle, but if other types of CNC operations (e.g. grinding or polishing) are also intended to be performed, then another, appropriate CNC processing unit may also be used.

CNC additional equipment

According to the customer’s wishes CNC LAMBDA VTL can be equipped with additional, optional auxiliary elements, such as measuring probes, tool magazines or cooling system (compressed air or oil mist). In order to enable the use of the machine to process a larger number of smaller-sized workpieces, the machine casing may be equipped with a loading door at both ends of the casing and in the side walls, and the working space may be further divided by internal, openable partitions into several treatment zones. The ability to use the mobile tool magazine allows the machine to exchange them rapidly.

The use of CNC Lambda VTL

Due to the dimensional capabilities of the LAMBDA VTL series milling centers, they are mainly used by yacht and boat manufacturers. 5D milling machine (5-axis processing) is a machine tool for plastics, composites, aluminum, wood, thermoforming, laminating and casting models. Milling in wood and its derivatives (mdf, plywood, osb), dibond, plexiglass, PVC, polyethylene, polyamide - in the industry, the production of road and rail vehicles and in aviation. In yacht industry, it allows for a significant reduction in the processing of the components needed to build new vessels.