5 Axis CNC Machining Center

Gantry CNC Milling Machine for wooden furniture

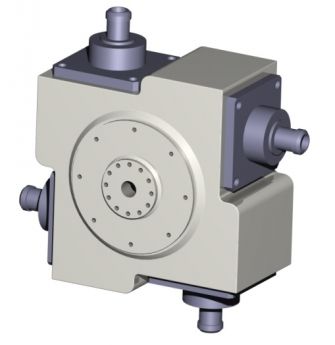

SIGMA ZM - 5-axis CNC machining center dedicated for the serial production of chairs, tables and furniture. An innovative combination of the CNC advantages:

- gate structure

- two independent machining fields

- automated detail hopper

allows to achieve unprecedented efficiency in alternating machining using the workpiece tray. The optimized design of the CNC machine also allows it to be used as a conventional gantry center with manual part loading and two independent machining fields.

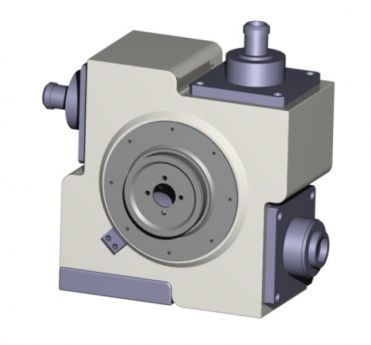

CNC machining head contain up to four 7.5kW or 10 kW electrospindes completes this design. The use of two or more inverters controlling electro-spindles makes it possible to minimize the time between work of subsequent tools.

Due to such versatility, the SIGMA ZM machining center - CNC milling machine is an excellent solution that can be used e.g. for manufacture of

- upholstered furniture,

- chairs and tables,

- plastics

- aluminum models and molds.

Three modes of operation – adjust the machine to your current production needs

Sigma ZM can work in fully automated mode due to the use of component feeders in both machining areas. A special support rack for component feeder trays allows them to slide into the stationary area to provide one or two work areas when manual mounting is required, such as with 3-dimensional components of larger sizes.

Automatic workpiece clamp set-up cycle

Sigma Fast ZM has a patented automatic workpiece positioning clamp system allowing fast and precise set-up of the machine operation for any component, even in the case of workpieces curved along two planes!