3-axis Trio SP CNC Machining Center for Aluminum

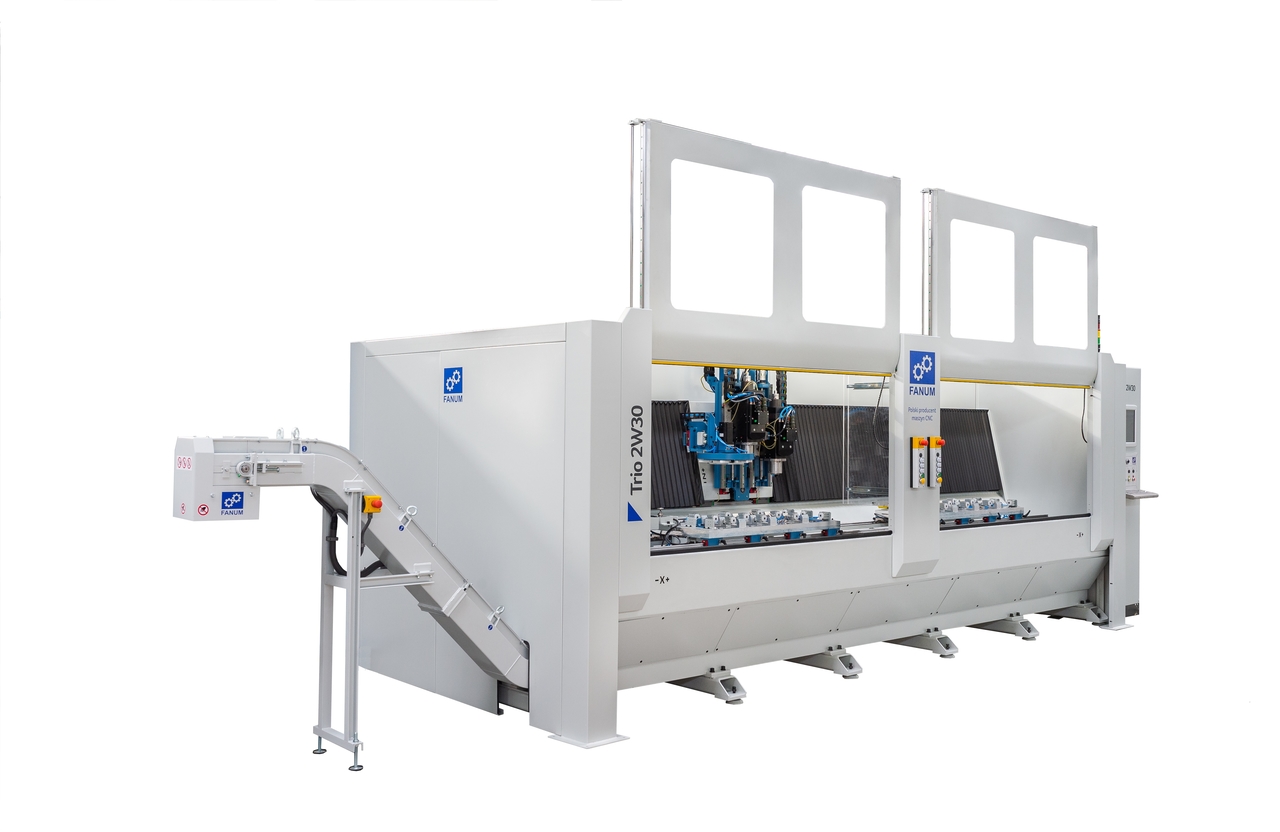

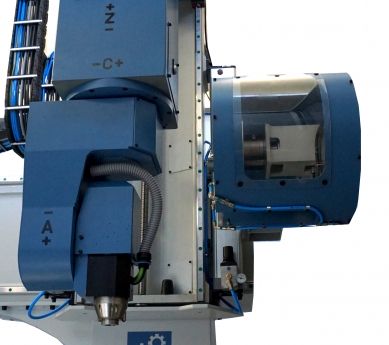

Trio SP is an industrial 3-axis CNC machining center for high-performance machining of aluminum profiles, molds and models. This specialized CNC machine is equipped with modern, multiplied machining units composed of a main spindle with its own tool magazine. Each working unit is equipped with an independent Z axis. The prefabricated elements are mounted on specialized clamps or by vacuum. Ergonomic tables allow easy homing of workpieces and collection of finished parts. The size of each work field can be adapted to the customer's needs. The design of the CNC Trio SP machine allows the simultaneous machining of even a few details in sequential mode - when reloading in one work field, machining continues in the other field. The design of the machine ensures a very high level of operational safety, which is confirmed by the CE certificate. Chips are removed outside the working area using an automatic spoil conveyor.

The innovative control system used in Trio SP is created to work in the INDUSTRY 4.0 system (digital industry). The extensive interface fully cooperates with SMART FACTORY systems to increase efficiency in production management through the use of intelligent devices and new technologies. The system enables, among others, coupling the machine tool with an automatic loading and unloading system, as well as remote diagnostics and management of the machine service, through ongoing monitoring of the technical condition. Thanks to this, you can easily plan the necessary inspections, maintenance and replacement of components in advance that require it to avoid sudden repairs in emergency mode. Parameters such as the current state of the electro-spindles (load level, winding temperature, bearing temperature, etc.) are monitored.