Hybrid Manufacturing System

Innovative solution combining large-scale 3D Printing and 5 axis Milling

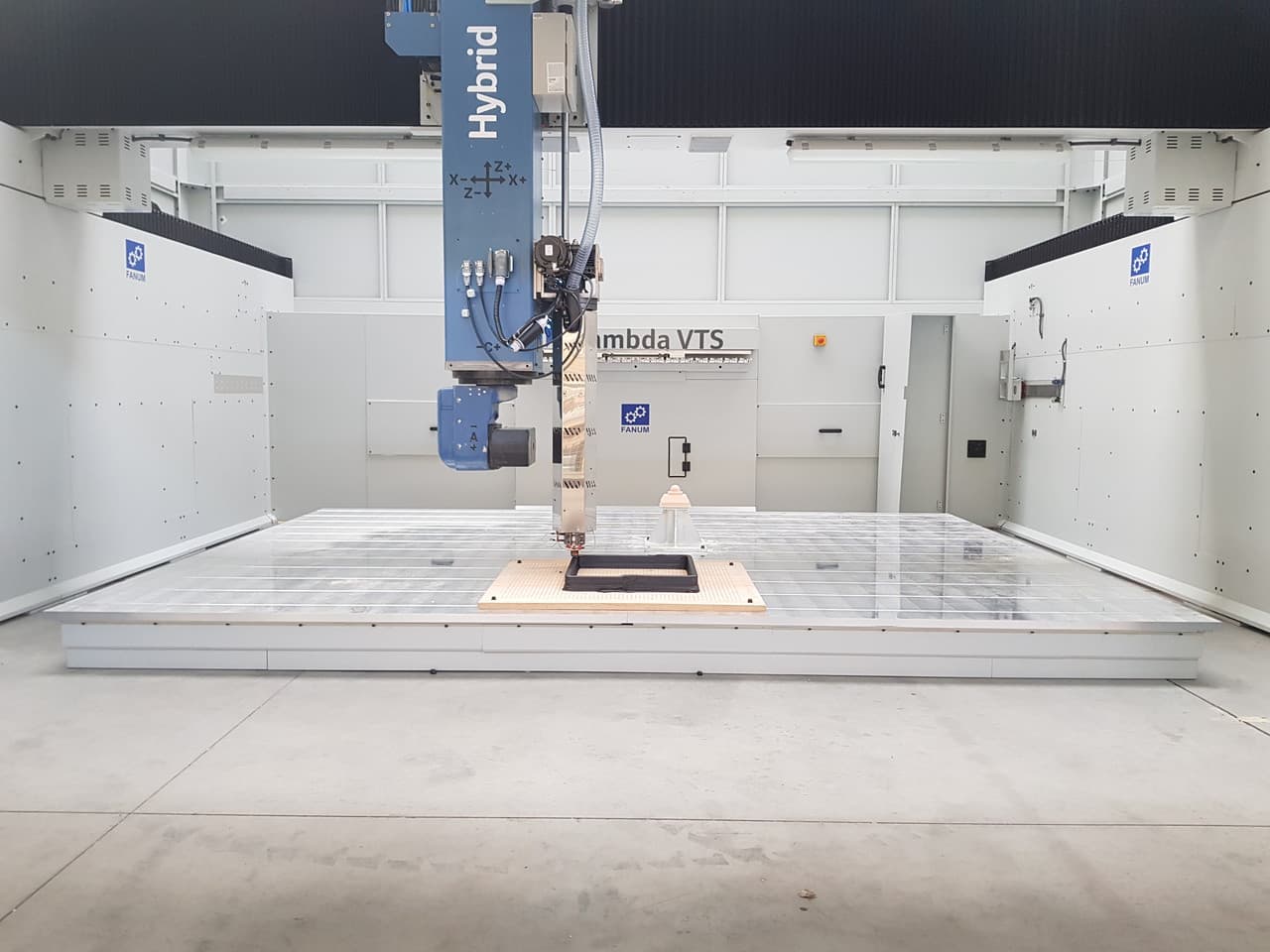

FANUM developed and implemented an additive manufacturing (AM) which is large scale 3D printing technology to 5-axis CNC milling machine. This advanced hybrid manufacturing system enables 3D printing of models and then milling them to the required tolerances and accuracy on one and the same CNC machine.

Hybrid manufacturing system

Hybrid manufacturing system uses the mechanical base of standard FANUM machines: Lambda VTS-VTM-VTL series, Lambda GT and ST, Sigma ST, Trio NT. The printhead is moved by the CNC milling machine axes. This allows normal use of the milling machine in 5-axis operations such as milling, drilling, cutting, threading, etc., when the extruder is in the magazine outside the work area.

Adaptation of the milling machine for 3D printing is done by hanging the head next to the spindle (for G.12 and G20) or adding an additional print bar (for G.50 and higher capacities).

There are four series of printheads available:

- series G.12 with capacity up to 12kg/h

- series G.20 with a capacity of up to 20kg/h

- series G.50 with a throughput up to 50kg/h

- series G.200 with a capacity of up to 200kg/h

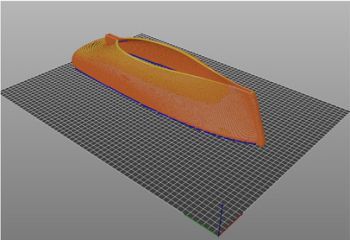

For more efficient work, we integrated the print head with the control of the milling machine by adding a servo drive. You can print in a typical planar way (90deg) or at a 45deg angle, which makes it possible to print, e.g. boat hull profiles without supports.

3D Printing parameters

- Extruder capacity 12-200 kg/h

- Extrusion temperature 260 °C, 400 °C

- Printing nozzles 4-25 mm

- 3D printer work area similar to machining ranges

- Printing speed up to 20 m/min

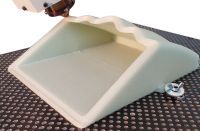

3D printing combined with CNC milling overcomes the limitations of the pure additive method. Nozzles with high material flows allows the production of near net shape parts. Printing accuracy does not have to be perfect, as the required shape of the part can be achieved by milling.

3D printing materials

Materials developed by our specialists are perfect for cnc machining and after using the model can be recovered by a regranulation line.

- Basic materials: PE, PP

- Reinforced materials with: carbon, glass or natural fiber

- On special request: ABS, PLA, PA, PC, PET, PPS, PEEK, PEKK

CNC operator training

We provide professional training for operators. During the training we teach to use programs for cutting models (slicers) and we modify our postprocessor to customer’s machine g-code specification.

3D Printing applications

- Prototyping

- Molds

- Small batch production

- Production process support

Download Hybrid manufacturing system

catalague in pdf

Fanum

- Wielopole Skrzyńskie 11B

- 39-110 Wielopole Skrzyńskie

- NIP: 818-16-55-251

- tel. +48 17 22 14 880

- tel. kom. +48 693 106 725

- tel. kom. +48 609 311 200

- tel. kom. +48 607 581 558