FANUM CNC machines control sytem

FANUM CNC machines are available with OSAI, HEIDENHAIN, SIEMENS control system.

CNC SOFTWARE: VisioCNC, PCX, CAD / CAM

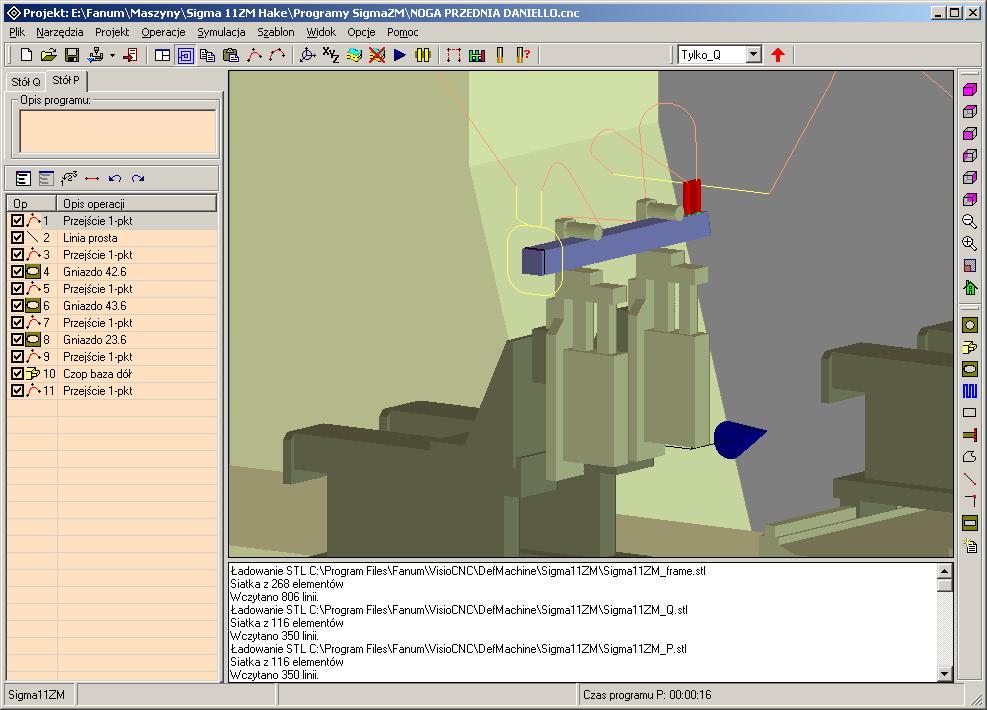

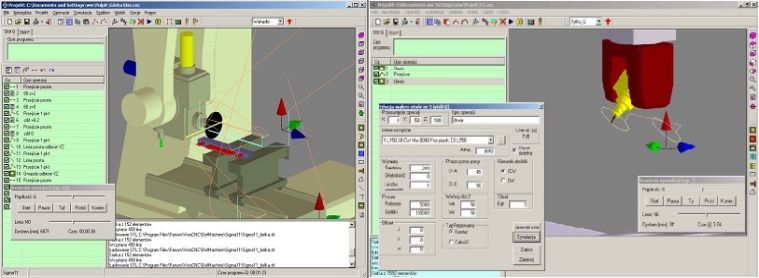

VisioCNC - The FANUM program for the CNC machine designed to visualize and simulate.

3D simulator

All Fanum CNC machines are equipped with personalized VisioCNC software. This program is used to create and edit machining programs created by most CAD / CAM systems available on the market. Testing, simulating and optimizing transitions between operations are just some of the features that this cnc software has.

VisioCNC fully reflects all the functions of the numerical controller, which means that the software is 100% compatible with the machine. The advantage of our software is that it also allows you to create parametric macro-type subroutines. Basing the simulation directly on G-codes compliant with ISO standards makes it possible to accurately reproduce the operation of the controller, which makes VisioCNC an excellent tool for program control, detection and correction of possible collisions both during machining and in machine adjustments.

Friendly interface

VisioCNC is characterized by a clear and easy to use interface developed in Polish. However, installing another language is not a problem. It is possible to upload any language version for the convenience of use.

The program allows you to easily calculate the actual machining times, which makes it easier to perform accurate cost calculations at the initial stage of production preparation, without the need to carry out time-consuming, physical tests. The possibility of eliminating potential collisions and optimizing the tool path, already at the program development stage, significantly reduces the implementation time of the planned production, and above all helps to determine the duration of the machining program to the optimal value.

Parametric macros

VisioCNC allows you to create machining programs based on specialized subroutines - parametric macros that describe repetitive operations, such as drilling, tenoning, making spigot seats, planning, cutting and milling basic contours. The program optimizes the tool paths to reduce machining times as much as possible. VisioCNC has the function of creating a mirror image processing (especially useful when programming the processing of symmetrical details, such as e.g. chair elements).

CAD / CAM systems

One of the core features of VisioCNC is the ability to import and optimize NC code created by other CAD / CAM systems (eg AlphaCAM, NX HyperMill, SolidCAM, SolidWorks) to suit the cnc machine and optimize inter-operation transitions. Fanum machining centers can also cooperate with any CAD / CAM system available on the market and dedicated for use in carpentry. The selection of the optimal CAD / CAM system depends on the profile of the anticipated production, the degree of intuitiveness of its use, the quality of the generated NC code, as well as the experience of programmers and should be adapted to the individual conditions of the future user.

CNC Machine Software

|

|

|

Basic features of the program:

- toolpath optimization

- visualization of machine operation

- checking the limits of interpolated axes

- minimizing production times

- autocorrect

- anti-collision module

Built-in parametric macros

The VisioCNC program has a number of pre-prepared parametric macro programs that enable the design of many basic machining operations without the use of external CAM software. This program also allows you to extend your own macro programs.

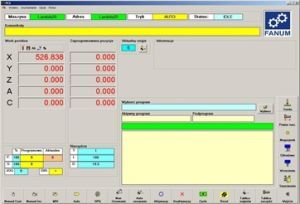

FANUM machines management software features:

- intuitive and simple interface

- quick access to the machine's most important options

- extensive machine diagnostics

- quick axis overrun checks in ISO programs

- advanced operation of component and tool probes

PCX - program for easy operation of all machine functions

|

PCX software is an interface supporting the operator in standard operations, such as:

|

|

|

Hole calibration window with a measuring probe Tool measurement window |

CAD / CAM SOFTWARE

FANUM CNC machining centers can cooperate with any CAD / CAM software on the market. Choosing the right software should be dependent on the expected production profile, intuitive programming, the quality of the generated G-code, as well as the preferences of developers. Advanced 3D CAD software used in the design of machine tools, gives you a thorough analysis of every aspect related to the operation of CNC machine before it is manufactured.

We cooperate with suppliers of following CAM software, such as:

SolidCAM NX AlphaCam EdgeCAM V-Carve CobusHypermill Catia Delcam TopSolid PowerMill SolidWorks |

|---|

|

Reverse engineering

Both the professional 3-dimensional scanner and touch sensitive measuring rails allow the transfer of physically existing solids to the CAD/CAM software in the form of a map of points facilitating the production of a surface model or finished surface.

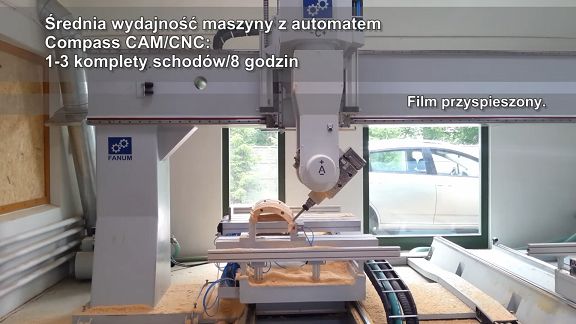

Compass Software CAD10 DXF/CAM/CNC

program for the construction and production of stairs on FANUM CNC machines

Compass Software provides software that automates the production of stairs. Prepared solutions are ready to control cnc machines.

CAM / CNC is a postprocessor prepared by Compass for a given machine. The user decides which tools to use and how to process a given element (e.g. whether to smooth the contour or not and with what tool, simple elements with a milling cutter or saw, or chamfering with a profiler, etc.)

Production with ready-made settings is fast, extremely easy and fully automatic. A ready numerical code is created for a given CNC machine together with the file needed by the laser. Everything else: when the machine is to depart (to collect the cut waste), whether the correct sequence of operations is automatically generated by the Compass postprocessor.

Cooperation with the 3D measuring system

Compass software allows you to import a laser stair scan to Compass CAD10. The measurement of the stairs is performed with a 3D projection laser. DXF files can be imported into programs that come with the CNC machine

Compass CAM / CNC is the most frequently chosen system in Poland in companies that produce stairs.

Video from the implementation of Compass CAD / CAM / CNC 10 on a FANUM machine

Video from the implementation of Compass CAD / CAM / CNC 10 on a FANUM machine