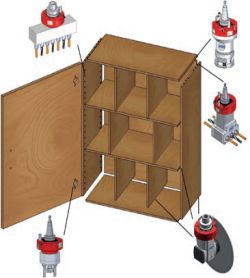

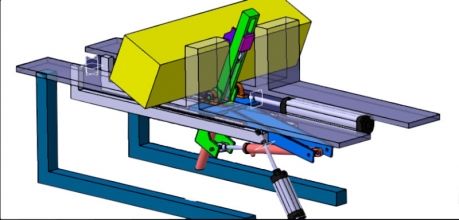

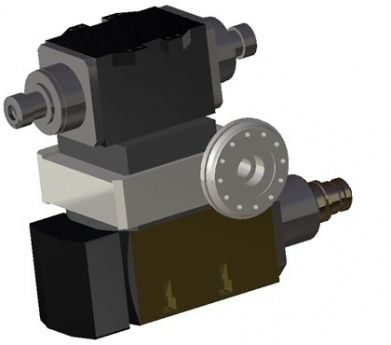

The angular aggregate is the most frequent form of change aggregates for CNC-machining centres.

They offer a horizontal processing with vertical working spindle, in most cases being available as saw aggregate, boring aggregate or lock case milling aggregate.

The term "lock case milling aggregate" in the narrower sense describes a horizontal milling aggregate in CNC-machining centres, which is specifically meant for milling the opening for the insertion of the lock case on board doors.

In a wider sense, the term describes all types of horizontal milling aggregates, which are good for milling openings for lock cases. This includes even the aggregate for tool changers, which can be used as lock case milling aggregate.

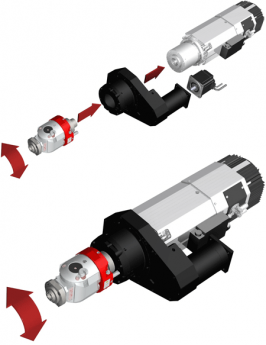

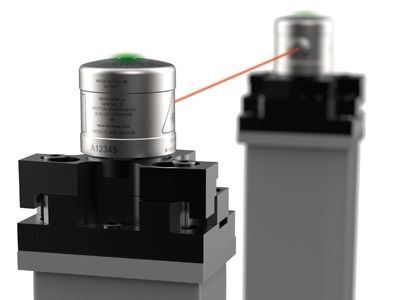

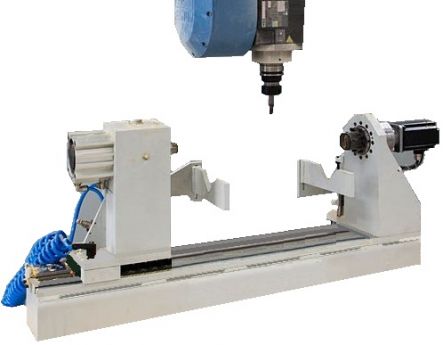

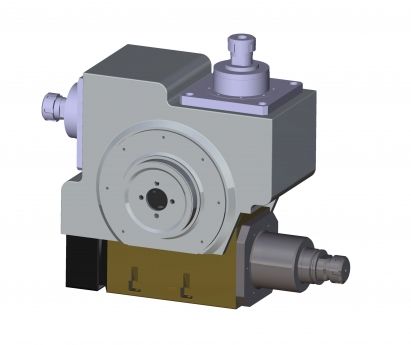

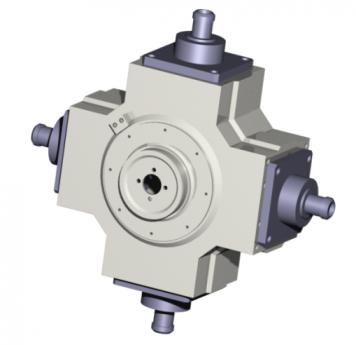

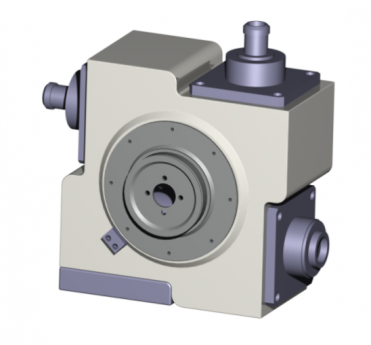

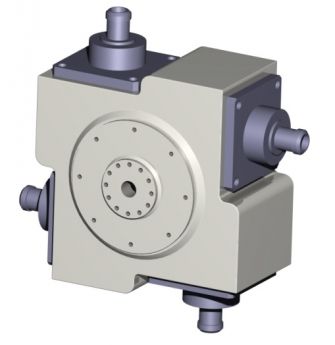

Angle aggregates for the CNC HSK ISO electrospindle

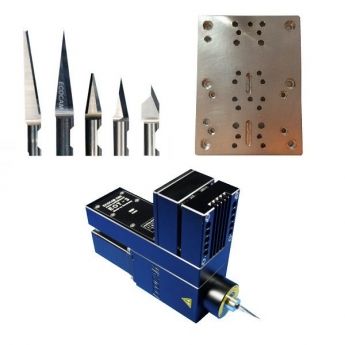

Drilling - cutting - milling aggregates

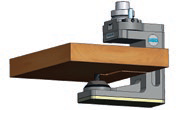

Increased capabilities of machining centers - machining of inaccessible places

Angle aggregates intended for electrospindles enable a wide range of machining operations. Thanks to the head design, the tool can reach previously inaccessible parts of the workpiece, e.g. inside housings or openings.

Angle aggregates working on the C axis on the spindle with pneumatic tool change allow to work in 4 axes:

- drilling, reaming, countersinking, tapping

- milling side drillings, milling grooves for locks,

- saw cutting of materials.

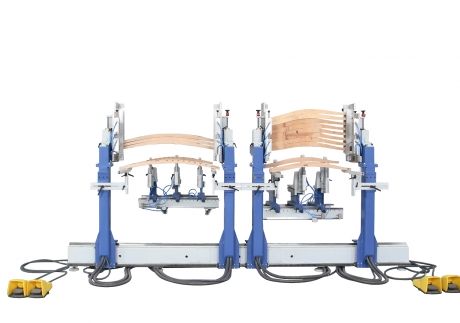

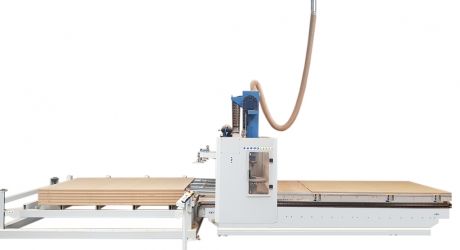

The functionality of CNC aggregates is particularly appreciated in the industry dealing with wood, composite and mold processing. They are used where elements require heavy processing, have non-standard shapes and sizes.

CNC aggregates reduce costs

CNC aggregates provide the possibility of multi-axis machining on the existing three and four-axis centers with optimal efficiency. They allow you to work with one mounting, which saves time and allows you to eliminate errors. Angle aggregates are suitable for use in all available types of machining centers.

Available aggregates for electrospindles:

- drilling units for vertical and / or horizontal drilling,

- angular aggregates with adjustable machining angle.

We use aggregates from proven and reputable manufacturers such as HSD or HITECO.

All HSK and ISO units are made of aluminum to guarantee solid construction and long-term durability. Every mechanical, pneumatic and electronic component used in the HSD angle head undergoes a double testing phase that guarantees optimal quality standards.