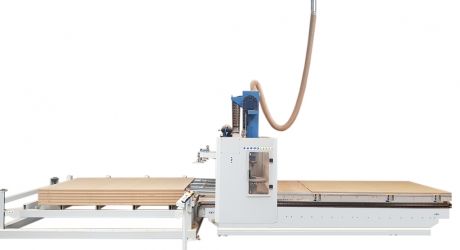

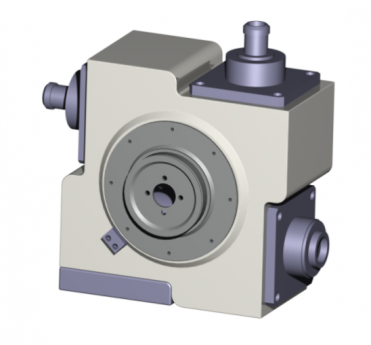

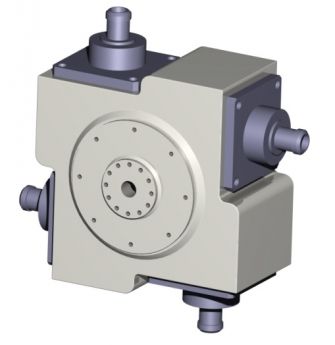

Stationary dust and chip extraction for FANUM CNC machines

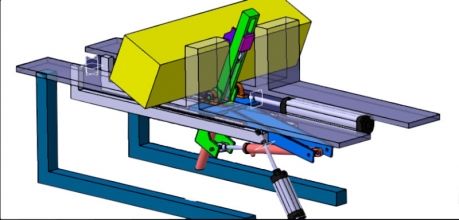

The station extractor is intended for indoor installation, for the filtration of dry dust and chips. It is made in a version with an inlet from the top or from the bottom

Stationary filter with SFW storage bags, overpressure, is designed for installation inside (filters with a capacity of up to 8,000 m3 / h) or outside production rooms (filters with a capacity from 5.5 to 15,000 m3 / h).

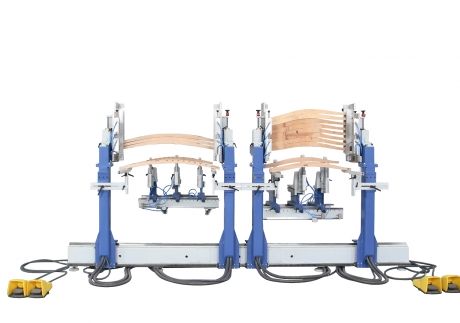

CNC wood processing leads to high concentration - deposition of dust, sawdust. This may result in an environment with an explosion hazard which is not desirable. Suction and filtering devices are designed to extract sawdust and dust as close to their formation as possible. Single woodworking machines with a central suction pipe are connected to suction of sawdust and dust, which ensures suction of sawdust and dust and their discharge to the filtering suction devices where the sawdust and dust are disconnected from the suction air.

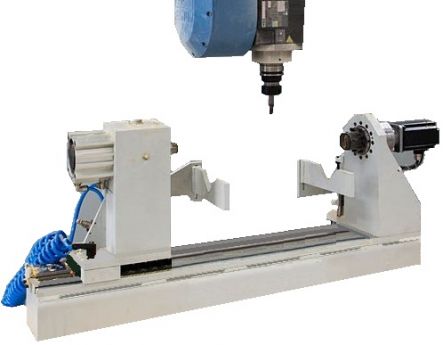

FANUM CNC machines are adapted to be connected to a dedusting installation (central or stationary dust collector).

The system includes:

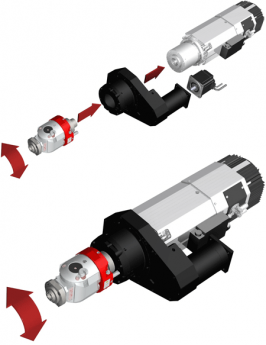

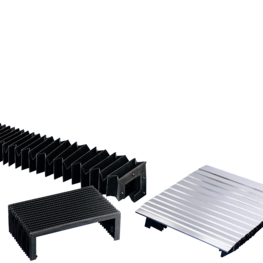

● dust extraction hood with brush cover, lifted pneumatically,

● flexible pipe connecting the hood with the nozzle

● a connector for connecting the external installation.

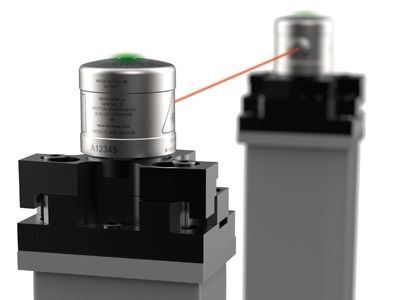

The products have approvals and certificates that meet all the necessary standards needed for inspection by an inspector in your plant and ensure safe work.

POLISH PRODUCTION

DURABLE CONSTRUCTION

How it works

In mobile bag filters, the separation of pollutants takes place: heavy particles fall into the lower bag, the lighter ones settle on the inner surface of the filter bag (upper) made of anti-static cotton filter cloth. In stationary bag filters, polluted air goes to the expansion chamber, where heavier and coarser impurities fall to the bottom of the filter under the influence of the cyclone effect. Then the air goes to the filter inserts chamber, where fine dust fractions are captured on the filter surface. Accumulation of dust on the filter surface leads to an increase in flow resistance, which is manifested by an increase in the pressure difference. These particles are shaken off by making the bags vibrate by an electric vibrator to which they are attached or by flapping pulses of compressed air.

Use

Stationary bag filters can be located both inside and outside the facility. In the case of mobile filters, the dusty air is sucked directly from the emission source by means of a flexible pipe or a self-supporting suction arm, while stationary devices are designed to operate the installation consisting of local exhausts.